Общее руководство по работе с инженерным программным комплексом DEFORM, Таупек И.М., Кабулова Е.Г., Положенцев К.А., Лисовский А.В., Макаров А.В., 2015

Учебное пособие описывает основные принципы работы с инженерным программным комплексом DEFORM, разработанным американской компанией Scientific Forming Technologies Corporation (SFTC) и предназначенным для анализа технологических процессов обработки металлов давлением и термической обработки. В пособии рассматриваются вопросы подготовки исходных данных для расчёта, включающие особенности подготовки моделей, задания свойств материалов и управления движением рабочим инструментом, а также возможности редактирования встроенной базы данных материалов. Приводятся рекомендации по выполнению моделирования различных процессов ОМД и термообработки. Пособие полезно для инженеров-технологов, научных работников, аспирантов и студентов, занимающихся вопросами и проблемами процессов обработки металлов давлением и термической обработки.

Введение.

DEFORM специализированный инженерный программный комплекс, предназначенный для анализа процессов обработки металлов давлением, термической и механической обработки, разработанный американской компанией Scientific Forming Technologies Corporation (SFTC), являющейся лидером в области моделирования процессов обработки металлов давлением. DEFORM позволяет моделировать практически все процессы, применяемые в обработке металлов давлением (ковка, штамповка, прокатка, прессование и др.), а также операции термической обработки (закалка, старение, отпуск и др.) и механообработки (фрезерование, сверление и др.). Это делает DEFORM мощным инструментом, позволяющим проверить, отработать и оптимизировать технологические процессы, используя на различных этапах исследований только компьютер, а не дорогостоящие эксперименты на производстве. Благодаря этому появляется возможность проверить множество вариантов рассматриваемого процесса, что существенно повышает точность и достоверность полученных результатов исследований, а также возникает возможность буквально заглянуть внутрь заготовки. Программный комплекс применяется по всему миру, как на промышленных предприятиях, так и в научно-исследовательских институтах и технических университетах, является самым распространенным программным комплексом для моделирования процессов обработки металлов давлением, заслуженно считается одной из наиболее точных системой для моделирования сложных трехмерных процессов пластического деформирования металлов.

Содержание.

Введение.

1. Подготовка исходных моделей.

2. Препроцессор DEFORM-3D.

2.1 Загрузка моделей и присвоение свойств материала объектам.

2.2 Настройка конечно-элементной сетки.

2.3 Настройка окон плотности конечно-элементной сетки.

2.4 Настройка граничных условий.

2.5 Настройка параметров расчета.

2.6 Настройка движения объектов.

2.7 Создание базы данных и запуск расчета.

3. Постпроцессор DEFORM-3D.

3.1 Настройка отображения рассчитанных параметров процесса.

3.2 Построение графиков энергосиловых параметров.

3.3 Отображение контактных поверхностей.

3.4 Задание и отслеживание отдельных точек в конечно-элементной сетке.

3.5 Задание координатных сеток.

3.6 Задание разрезов и сечений.

3.7 Настройка многооконного режима.

3.8 Настройка размеров изображения для сохранения результатов.

3.9 Управление и сохранение анимации.

3.10 Настройка различных цветовых схем для шкалы отображения.

4. Использование плоскостей симметрии при моделировании.

5. Использование плоской задачи при моделировании.

5.1 Создание и подготовка применяемых моделей.

5.2 Работа с Препроцессором модуля DEFORM Integrated 2D/3D.

5.3 Работа с Постпроцессором DEFORM Integrated 2D/3D.

6. Создание и редактирование реологических моделей материалов.

7. Моделирование операций термообработки.

7.1 Подготовка моделей.

7.2 Препроцессор модуля «Термическая обработка».

7.3 Просмотр результатов в Постпроцессоре.

8. Особенности моделирования некоторых процессов ОМД.

8.1 Моделирование прокатки.

8.2 Моделирование волочения сплошного профиля.

Библиографический список.

Приложение.

Бесплатно скачать электронную книгу в удобном формате, смотреть и читать:

Скачать книгу Общее руководство по работе с инженерным программным комплексом DEFORM, Таупек И.М., Кабулова Е.Г., Положенцев К.А., Лисовский А.В., Макаров А.В., 2015 — fileskachat.com, быстрое и бесплатное скачивание.

Скачать pdf

Ниже можно купить эту книгу по лучшей цене со скидкой с доставкой по всей России.Купить эту книгу

Скачать

— pdf — Яндекс.Диск.

Дата публикации: 21.02.2022 11:20 UTC

Теги:

Таупек :: Кабулова :: Положенцев :: Лисовский :: Макаров :: 2015 :: DEFORM :: инженерия

Следующие учебники и книги:

- Введение в лазерные технологии, опорный конспект лекций по курсу «Лазерные технологии», Вейко В.П., Петров А.А., Самохвалов А.А., 2018

- Стеклодувное дела, Веселовский С.Ф., 1952

- Организация движения на железнодорожном транспорте, Боровикова М.С., 2003

- В мире занимательных фактов, Земляной Б., Чевокина Ю., 1963

Предыдущие статьи:

- Информационно-документационная деятельность, Ташлыкова А.Н., Рябиничева Т.Н., Ночка Е.И., 2016

- Дороги мира, История и современность, Иванов И.А., 2017

- История декоративно-прикладного искусства, От древнейших времён до наших дней, де Моран А., 1982

- Инженерные расчеты при разработке нефтяных месторождений, Том 1, Скважина — промысловый сбор, Артемьев В.Н., Ибрагимов Г.З., Иванов А.И., 2004

Автор:В.С. Паршин, А.П. Карамышев, И.И. Некрасов, А.И. Пугин, А.А. Федулов

Название: Практическое руководство к программному комплексу Deform

Издательство: УРФУ

ISBN: 978-5-321-01772-2

Год: 2010

Формат: JPG

Размер: 391МВ

Страниц:267

Язык:Русский

Учебное пособие посвящено системному описанию принципов работы с программным комплексом DEFORM-3D американской фирмы Scientific Forming Technologies Corporation (SFTC), направленным на проведение конечно-элементного анализа различных технологических процессов металлообработки. Пособие затрагивает вопросы создания инструмента и заготовки, их разбиения конечными элементами, назначения механических свойств, граничных условий, управления работой процессора. Приведены также примеры решения задач с применением рассматриваемого программного комплекса, что придает учебному пособию особую практическую ценность. Пособие полезно для инженеров-разработчиков, научных работников, аспирантов и студентов, в особенности занимающихся исследованиями технологических процессов и оборудования в области обработки металлов давлением.

Автор:

KorovnikovAV · Опубликовано: 23 минуты назад

А потом позвонил

Крокодил

И со слезами просил:

— Мой милый, хороший,

Пришли мне калоши,

И мне, и жене, и Тотоше.

— Постой, не тебе ли

На прошлой неделе

Я выслал две пары

Отличных калош?

— Ах, те, что ты выслал

На прошлой неделе,

Мы давно уже съели

И ждем, не дождемся,

Когда же ты снова пришлешь

К нашему ужину

Дюжину

Новых и сладких калош!

Имею спросить, обувью питаешься?

Чтобы что? На английском говорит 1,5 миллиарда человек, и 90% из них за орфографию и произношенипроизношение учительница города Асбест Свердловской области поставила бы в лучшем случае трояк. Однако все всех понимают.

Классики говорили «не делайте из еды культа», так вот, перефразирую — » Не делайте из орфографии культа». Если ты душнила по орфографии с тобой никто особо говорить не захочет дальше «пакет нужен»?

D

EFORMTM—3D

Лабораторные

работы

1.

Препроцессор

1.1.

Создание новой задачи

1.2.

Установка параметров расчета

1.3.

Загрузка данных объекта

1.4.

Управление экраном

1.5.

Выбор точки

1.6.

Другие кнопки окна Экран (DISPLAY)

1.7.

Сохранение задачи

1.8.

Выход из DEFORM-3D

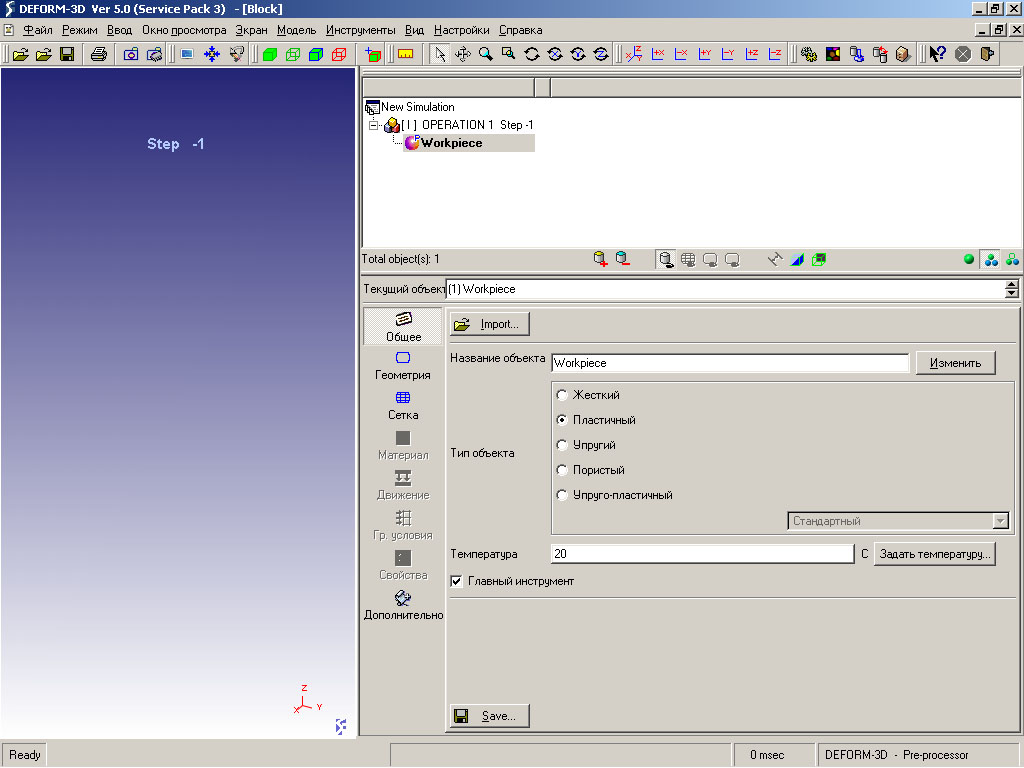

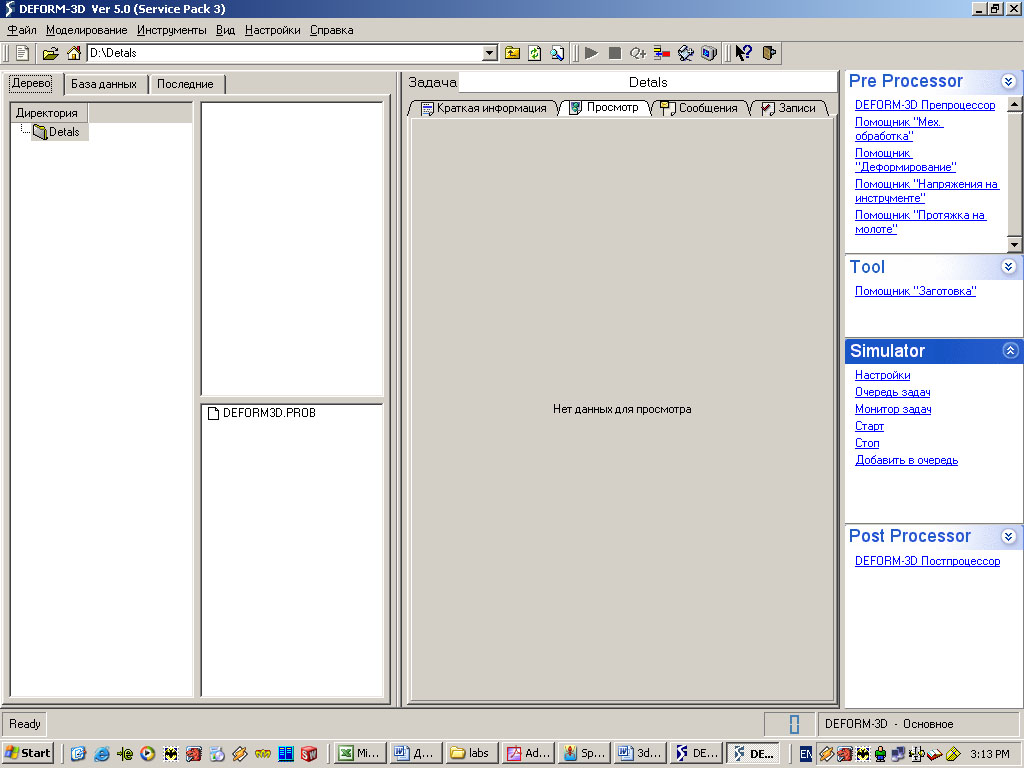

1.1. Создание новой задачи

На unix-машине введите

DEFORM3 для запуска DEFORM™-3D. На

Windows-машине нажмите кнопку

и выберите DEFORM-3D из меню. Откроется

главное (MAIN) окно DEFORM-3D, как показано

ниже.

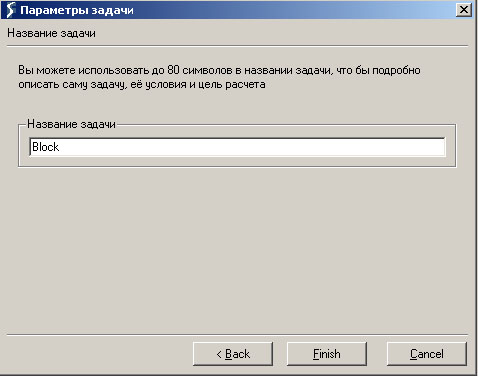

Создайте новую задачу

выбрав Файл>Новая задача или нажав

кнопку Новая задача

.

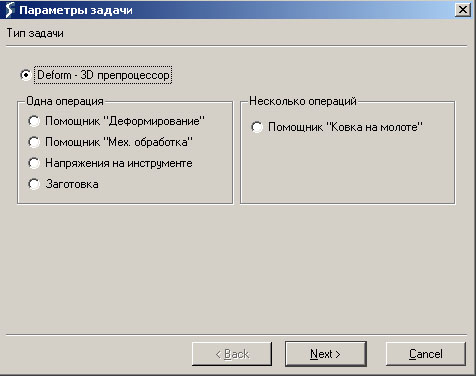

Появиться окно

Параметры задачи. Используйте

установки по умолчанию для запуска

препроцессора DEFORM-3D (не используйте ни

один из мастеров) и нажмите кнопку

.

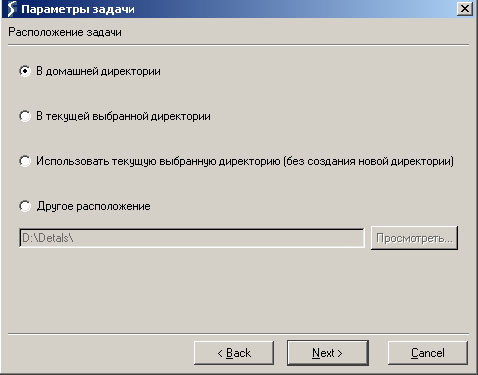

Нажмите кнопку

для определения расположения новой

задачи как ’В домашней директории’.

В поле Название

задачи, введите Block и нажмите

кнопку

.

Будет открыт препроцессор

DEFORM-3D. Препроцессор разделен на несколько

различных секций — называемых Экран,

Дерево Объектов и Данные Объектов.

Вверху экрана также находится ряд

кнопок. Эти кнопки будут описаны, так

как они встречаются в лабораторных

работах. Наиболее важные из этих кнопок

находятся справа вверху. Из-за их

важности дается краткое описание

каждой:

|

Кнопка |

Назначение |

Описание |

|

|

Настройки задачи |

В этом меню определяются все параметры |

|

|

Материал |

В этом меню определяются свойства |

|

|

Позиционирование объектов |

С помощью этого элемента управления |

|

|

Взаимодействие объектов |

В этом меню определяются отношения |

|

|

Генерация базы данных |

Когда все операции препроцессора |

|

|

Выход |

С помощью этой кнопки осуществляется |

Дерево Объектов

Данные Объектов

1 Экран .2. Установка параметров расчета

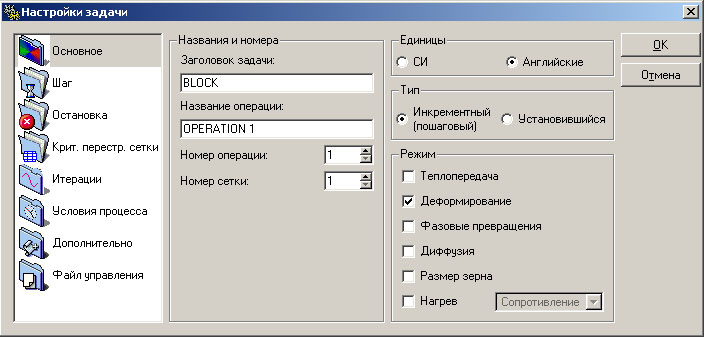

Нажмите кнопку

для открытия окна Настройки задачи.

Измените Заголовок задачи на Block.

Убедитесь, что Единицы измерения

установлены как English и выбран пункт

Деформации (помечен флажком). Для

завершения нажмите кнопку

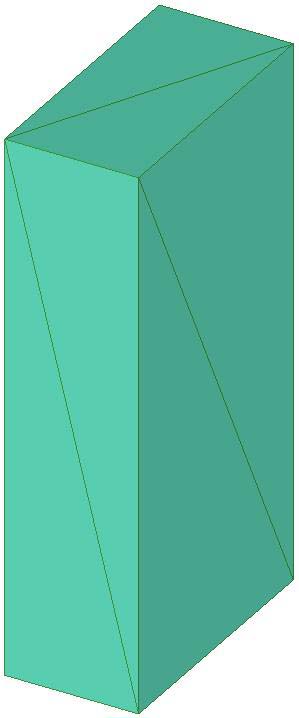

1.3. Загрузка данных объекта

Добавьте объект в

задачу, нажав кнопку Добавить объект

внизу Дерева объектов. Измените

Название объекта с Object 1 на Block

и нажмите

.

Установите Тип Объекта – Пластичный

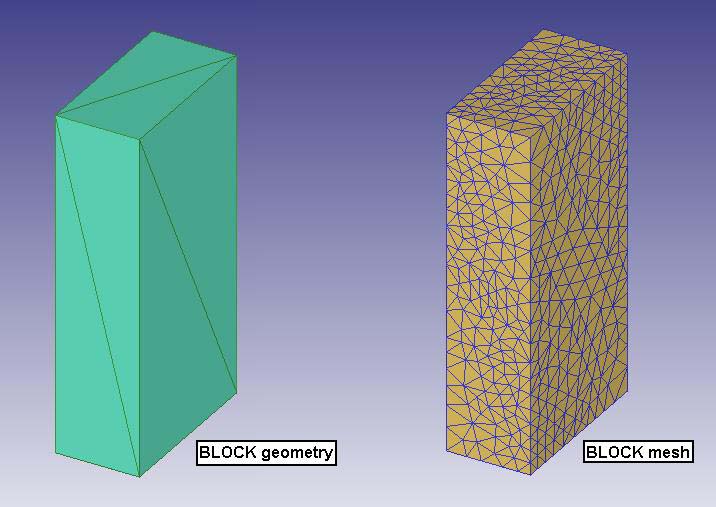

(Plastic). В DEFORM поверхность объекта

называется геометрия. Для импорта

геометрии объекта нажмите кнопку

и затем кнопку

.

Самый общий тип файлов

для импорта геометрии в DEFORM-3D –

стереолитография -.STL файл. Геометрия

для блока находится в файле Block_Billet.STL

папке DEFORM3DV5.0Labs. Найдите этот файл,

выберите его и нажмите кнопку

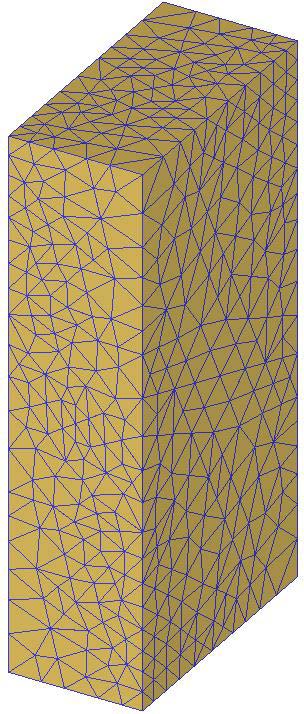

для импорта геометрии в DEFORM. Геометрия

прямоугольного блока должна появиться

Окне экран.

Теперь, когда определена

геометрия Блока, может быть сгенерирована

конечно-элементная сетка объекта.

Нажмите

для открытия окна Управление разбиением

сетки.

Нажмите кнопку

,

чтобы увидеть как выглядит поверхностная

сетка при использовании настроек по

умолчанию. Так как поверхностная сетка

выглядит хорошо, нажмите кнопку

для завершения процесса построения

сетки. Когда построение сетки завершится,

объект должен иметь 5000 элементов,

которые можно увидеть в Дереве Объектов

или в разделе Сводка окна Управление

разбиением сетки.

Соседние файлы в предмете [НЕСОРТИРОВАННОЕ]

- #

- #

- #

- #

- #

- #

- #

- #

- #

- #

- #

Лабораторные работы. — Москва: Инжиниринговая компания Артех, 2008. — 98 с.

DEFORM-3D – мощная система моделирования технологических процессов, предназначенная для анализа трехмерного (3D) поведения металла при различных процессах обработки давлением. DEFORM-3D предоставляет важную информацию о течении материала в штампе и распределении температур во время процесса деформирования.

DEFORM-3D позволяет моделировать такие процессы как: ковка, горячая, полугорячая и холодная штамповка, прессование, прокатка, вытяжка и многие другие процессы.

Содержание

Препроцессор.

Позиционирование инструментов и препроцессор.

Расчет ковки и постпроцессор.

Квадратное кольцо.

Ковка – Перенос от печи к инструменту.

Ковка – Задержка на нижнем штампе.

Ковка – Удар 1.

Ковка – Замена штампа и Удар 2.

Анализ напряженного состояния инструмента.

Рулевая тяга.

Держатель.

Обжатие (протяжка).

-

1DEFORMTM 3D Version 6.1 (sp1)Users Manual

Oct 10th 2007

2545 Farmers Drive, Suite 200Columbus, Ohio, 43235Tel (614)

451-8330Fax (614) 451-8325Email [email protected] -

2Table of ContentsPREFACE TO THIS MANUAL

…………………………………………………………………..6Chapter 1. Overview of

DEFORM…………………………………………………………………….

71.1 DEFORM family of products

……………………………………………………………………………….

71.2 Capabilities

……………………………………………………………………………………………………..

81.3. Analyzing manufacturing processes with DEFORM

…………………………………………….. 111.4. Before

you begin

……………………………………………………………………………………………

111.5. Geometry representation

…………………………………………………………………………………

121.6. The DEFORM system

…………………………………………………………………………………….

131.7. Pre-processing

………………………………………………………………………………………………

141.8. Creating input data

…………………………………………………………………………………………

141.9. File

system……………………………………………………………………………………………………

161.10. Running the simulation

………………………………………………………………………………….

171.11. Post-processor

…………………………………………………………………………………………….

171.12.

Units…………………………………………………………………………………………………………..

18Chapter 2. Pre-Processor

……………………………………………………………………………..

192.1. Simulation Controls

………………………………………………………………………………………..

192.1.1. Main controls

………………………………………………………………………………………………………

202.1.2. Step Controls

………………………………………………………………………………………………………

232.1.3. Advanced Step Controls

………………………………………………………………………………………..

262.1.4. Stopping

Controls…………………………………………………………………………………………………

292.1.5. Remesh Criteria

…………………………………………………………………………………………………..

312.1.6. Iteration

Controls………………………………………………………………………………………………….

312.1.7. Processing

Conditions…………………………………………………………………………………………..

372.1.8. Advanced Controls

……………………………………………………………………………………………….

392.1.9. Control

Files………………………………………………………………………………………………………..

432.2 Material

Data………………………………………………………………………………………………….

462.2.1. Phases and

mixtures…………………………………………………………………………………………….

472.2.2. Elastic data

…………………………………………………………………………………………………………

482.2.3. Thermal

data……………………………………………………………………………………………………….

512.2.4. Plastic

Data…………………………………………………………………………………………………………

522.2.5. Diffusion

data………………………………………………………………………………………………………

612.2.6. Hardness data [MIC]

…………………………………………………………………………………………….

632.2.7. Grain growth/recrystallization

model…………………………………………………………………………

642.2.8. Advanced material properties

…………………………………………………………………………………

702.2.9. Material data requirements

…………………………………………………………………………………….

712.3. Inter Material

Data………………………………………………………………………………………….

732.3.1. Transformation relation (PHASTF)

…………………………………………………………………………..

732.3.2. Kinetics model

(TTTD)…………………………………………………………………………………………..

742.3.3. Latent heat

(PHASLH)…………………………………………………………………………………………..

792.3.4. Transformation induced volume change (PHASVL)

…………………………………………………….

792.3.5. Transformation plasticity

(TRNSFP)…………………………………………………………………………

812.3.6. Other Transformation Data

…………………………………………………………………………………….

81 -

32.4 Object

Definition……………………………………………………………………………………………..

822.4.1. Adding, deleting

objects…………………………………………………………………………………………

832.4.2. Object name (OBJNAM)

………………………………………………………………………………………..

842.4.3. Primary Die

(PDIE)……………………………………………………………………………………………….

852.4.4. Object type (OBJTYP)

…………………………………………………………………………………………..

852.4.5. Object

geometry…………………………………………………………………………………………………..

872.4.6. Object meshing

……………………………………………………………………………………………………

952.4.7. Object material

…………………………………………………………………………………………………..

1072.4.8. Object initial

conditions………………………………………………………………………………………..

1072.4.9. Object

properties………………………………………………………………………………………………..

1082.4.10. Object boundary

conditions…………………………………………………………………………………

1152.4.11. Contact boundary

conditions……………………………………………………………………………….

1182.4.12. Object movement controls

………………………………………………………………………………….

1182.4.13. Object node

variables……………………………………………………………………………………….

1312.4.14. Object element variables

…………………………………………………………………………………..

1382.4.16. Data Interpolation

…………………………………………………………………………………

1452.5.1. Inter object

Interface…………………………………………………………………………………………..

1492.5.2. Positioning

……………………………………………………………………………………………………….

1622.5.3. Inter object boundary conditions

…………………………………………………………………………..

1642.6. Database Generation

…………………………………………………………………………………..

165Chapter 3. Running Simulations

…………………………………………………………………..

1673.1. Simulation Options

……………………………………………………………………………………….

1683.2. Switching between Solvers (Conjugate-Gradient and

Sparse)……………………………………. 1683.3. Multi Processing

…………………………………………………………………………………………..

1693.3. Email the Result

………………………………………………………………………………………….

1703.4. Starting the simulation

………………………………………………………………………………….

1703.5. Simulation graphics

………………………………………………………………………………………

1713.6. Add to Queue (Batch Queue)

…………………………………………………………………………

1723.7 Process Monitor

………………………………………………………………………………………….

1733.8. Stopping a simulation

……………………………………………………………………………………

1743.9. Troubleshooting problems

……………………………………………………………………………..

1743.9.1. Message file messages

……………………………………………………………………………………….

1743.9.2. Simulation aborted by user

…………………………………………………………………………………..

1743.9.3. Cannot remesh at a negative

step………………………………………………………………………….

1753.9.4. Remeshing is highly

recommended………………………………………………………………………..

1753.9.5Negative

Jacobian………………………………………………………………………………………………..

1753.9.6. Solution does not converge

………………………………………………………………………………….

1763.9.7. Stiffness matrix is non-positive

definite……………………………………………………………………

1793.9.8. Zero

pivot………………………………………………………………………………………………………….

1793.9.9. Extrapolation of data

…………………………………………………………………………………………..

1793.9.10. Bad Element

Shape…………………………………………………………………………………………..

1803.9.11. Inconsistent Step

Number…………………………………………………………………………………..

181Chapter 4: Post-Processor

………………………………………………………………………….

1824.1.Post-Processor Overview

……………………………………………………………………………….

1834.2 Graphical

display…………………………………………………………………………………………..

1844.2.1. Window

layout……………………………………………………………………………………………………

184 -

44.3.Post-Processing Summary

……………………………………………………………………………..

1934.3.1.Simulation Summary

……………………………………………………………………………………………

1934.3.2.State Variable

…………………………………………………………………………………………………….

195Displacement……………………………………………………………………………………………………………..

200Density……………………………………………………………………………………………………………………..

200Strain

……………………………………………………………………………………………………………………….

200Velocity

…………………………………………………………………………………………………………………….

202Normal

Pressure…………………………………………………………………………………………………………

202Temperature………………………………………………………………………………………………………………

202Volume Fraction

…………………………………………………………………………………………………………

202Grain Size

…………………………………………………………………………………………………………………

203Hardness…………………………………………………………………………………………………………………..

203Dominant atom

…………………………………………………………………………………………………………..

203User

Variables……………………………………………………………………………………………………………

2034.3.3.Point tracking

……………………………………………………………………………………………………..

2034.3.4.Load stroke

curves………………………………………………………………………………………………

2054.3.5.Coordinate Systems

…………………………………………………………………………………………….

2064.3.6. Step Selection & Manipulation

……………………………………………………………………………..

2074.3.7. Steps list

………………………………………………………………………………………………………….

2084.3.8.View Changes Within Viewport

………………………………………………………………………………

2104.3.9. Coordinate System

Selection………………………………………………………………………………..

2104.3.10.Rotation

…………………………………………………………………………………………………………..

2114.3.11.Coordinate Axis View

…………………………………………………………………………………………

2114.3.12.Point Selection

………………………………………………………………………………………………….

2114.3.13 Multiple Viewports

……………………………………………………………………………………………..

2124.3.14. Nodes

…………………………………………………………………………………………………………….

2124.3.15.

Elements………………………………………………………………………………………………………..

2134.3.16.

Viewport…………………………………………………………………………………………………………

2154.3.17. Data

Extraction…………………………………………………………………………………………………

2174.3.18.Flownet……………………………………………………………………………………………………………

2184.3.19. Mirroring

………………………………………………………………………………………………………..

2224.3.20 Animation controls and saving.

…………………………………………………………………………….

223Chapter 5: Elementary Concepts in Metalforming and Finite

Element Analysis …… 225Chapter 6: User Routines

……………………………………………………………………………

237User-Defined FEM

Routines………………………………………………………………………………………….

237User-Defined Post-Processing Routines

………………………………………………………………………….

2416.1. User defined FEM routines

……………………………………………………………………………

2416.2. User defined post-processing routines

…………………………………………………………….

267Quick

Reference…………………………………………………………………………………………

273Hot

Forming……………………………………………………………………………………………….

276Appendix A: Running DEFORM in text

mode………………………………………………………….

283Appendix B: Inserting DEFORM Animations in Powerpoint

Presentations ……………….. 287Appendix C: DETAILS OF

MOVEMENT CONTROLS IN SPIN.KEY …………………………..

289Appendix D: Data

Files……………………………………………………………………………………….

291Appendix E: 2D to 3D Conversion

Utility………………………………………………………………..

293Appendix F: Fracture with Element Deletion and Damage

Softening………………………….. 295 -

5Appendix G: Rotating Work piece Simulations

………………………………………………………..

300Appendix H: Sheet Forming in DEFORM-3D

………………………………………………………….

308Appendix I: Eulerian treatment of the 3D rolling process

………………………………………….. 317Appendix J:

Preventing leakage of nodes in sectioned simulations

……………………………. 318Appendix K: The Double

Concave Corner Constraint

……………………………………………… 321Appendix

L: Rolling Simulation Overview (In

Progress)…………………………………………….

324Appendix M: Checking the forming loads results of a simulation

……………………………….. 326Appendix N: Model setup

for steady state machining

……………………………………………… 328Appendix

O: Document on constructing linear friction

simulations……………………………… 336Appendix P: On

Using Spring-Loaded Dies

……………………………………………………………

345Appendix Q: THE DEFORM ELASTO-PLASTIC

MODEL…………………………………………. 347Appendix

R: Setting Up Multiple Processor

Simulations……………………………………………

353Appendix S: Coupled Die Stress Analysis…356Appendix T: Setting

up steady state extrusion357Appendix U: Setting up 3D machining

models365 -

6Preface to this manualThis manual describes the features and

capabilities of the DEFORM-3D system.It also contains a description

of the inputs and actions required to setup problemsand run

simulations. If you have not used DEFORM before we would

recommendthat you go through the lab manuals first for an

introduction on how to use thesystem and how to run different types

of simulations. The labs for DEFORM-3D,DEFORM-HT are provided as

PDF (Portable document format) documents whichcan be viewed using

Adobe Acrobat provided with DEFORM. All keywords whichare used in

DEFORM-3D are documented in the keyword reference manualswhich are

also provided as a PDF document. All documents can be accessedfrom

the help menus in the main program, pre-processor, and

post-processor.Overview of DEFORMPresents an overview of the DEFORM family of

products.Analyzing manufacturing processes with DEFORMDescribes how to

use DEFORM products to analyze manufacturingprocesses.The DEFORM systemIntroduces the DEFORM-3D system and describes

the components thatmake up the system.Pre-ProcessorDescribes the layout of the DEFORM

Pre-Processor.Running SimulationsDescribes how to run simulations and also how

to handle errors that occurduring simulations.Post-ProcessorDescribes post-processing results from simulations

and how to interpretresults.User RoutinesDescribes user FORTRAN routines in detail. DEFORM

allows the user towrite FORTRAN programs to describe the flow

stress, die speeds, damageaccumulation, and other features, as well

as defining and storing newvariables which can be tracked in the

post-processor along with the standardDEFORM variables.Release NotesContains release notes.

-

7Chapter 1. Overview of DEFORMDEFORM is a Finite Element Method

(FEM) based process simulation systemdesigned to analyze various

forming and heat treatment processes used bymetal forming and

related industries. By simulating manufacturing processes ona

computer, this advanced tool allows designers and engineers to:Reduce the need for costly shop floor trials and redesign of

tooling andprocesses.Improve tool and die design to reduce production and material

costs.Shorten lead time in bringing a new product to market.Unlike

general purpose FEM codes, DEFORM is tailored for

deformationmodeling. A user friendly graphical user interface

provides easy data preparationand analysis so engineers can focus

on forming, not on learning a cumbersomecomputer system. A key

component of this is a fully automatic, optimizedremeshing system

tailored for large deformation problems.DEFORM-HT adds the

capability of modeling heat treatment processes,including

normalizing, annealing, quenching, tempering, aging, and

carburizing.DEFORM-HT can predict hardness, residual stresses,

quench deformation, andother mechanical and material

characteristics important to those that heat treat.1.1 DEFORM family of products

DEFORM-2D (2D)Available on UNIX/LINUX platforms (HP, DEC, LINUX)

as well as personalcomputers running Windows-XP/Vista. Capable of

modeling plane strain oraxisymmetric parts with a simple 2

dimensional model. A full function packagecontaining the latest

innovations in Finite Element Modeling, equally well suitedfor

production or research environments.DEFORM-3D (3D)Available on UNIX/LINUX platforms (HP, DEC, LINUX)

as well as personalcomputers running Windows-XP/Vista.DEFORM-3D is

capable of modelingcomplex three dimensional material flow

patterns. Ideal for parts which cannot besimplified to a two

dimensional model.DEFORM-F2 (2D)Available on personal computers running Windows

XP/Vista. Capable ofmodeling-two dimensional axisymmetric or plane

strain problems. Suitable forsmall to mid-sized shops starting in

Finite Element Modeling.DEFORM-F3 (3D)Available on personal computers running Windows

XP/Vista. A powerful three-dimensional modeling package for

modeling cold, warm and hot forgingprocesses. -

8DEFORM-HTAvailable as an add-on to DEFORM-2D and DEFORM-3D. In

addition to thedeformation modeling capabilities, DEFORM-HT can

model the effects of heattreating, including hardness, volume

fraction of metallic structure, distortion,residual stress, and

carbon content.1.2 Capabilities

Deformation

Coupled modeling of deformation and heat transfer for simulation

of cold,warm, or hot forging processes (all products).Extensive material database for many common alloys including

steels,aluminums, titaniums, and super-alloys (all products).User defined material data input for any material not included

in thematerial database (all products).Information on material flow, die fill, forging load, die

stress, grain flow,defect formation and ductile fracture (all

products).Rigid, elastic, and thermo-viscoplastic material models, which

are ideallysuited for large deformation modeling (all

products).Elastic-plastic material model for residual stress and spring

backproblems. (2D, 3D).Porous material model for modeling forming of powder

metallurgyproducts (2D, 3D).Integrated forming equipment models for hydraulic presses,

hammers,screw presses, and mechanical presses (all products).User defined subroutines for material modeling, press modeling,

fracturecriteria and other functions (2D, 3D).FLOWNET (2D, PC,) and point tracking (all products) for

importantmaterial flow information.Contour plots of temperature, strain, stress, damage, and other

keyvariables simplify post processing (all products).Self contact boundary condition with robust remeshing allows a

simulationto continue to completion even after a lap or fold has

formed (2D, 3D).Multiple deforming body capability allows for analysis of

multipledeforming work pieces or coupled die stress analysis. (2D,

3D).Fracture initiation and crack propagation models based on well

knowndamage factors allow modeling of shearing, blanking, piercing,

andmachining (2D, 3D). -

9Heat Treatment Simulate normalizing, annealing, quenching,

tempering, and carburizing.Normalizing (not available yet)Heating a ferrous alloy to a

suitable temperature above the transformationrange and cooling in

air to a temperature substantially below thetransformation

range.Annealing A generic term denoting a treatment, consisting of

heating to and holdingat a suitable temperature followed by cooling

at a suitable rate, usedprimarily to soften metallic materials. In

ferrous alloys, annealing usually isdone above the upper critical

temperature, but the time-temperaturecycles vary both widely in

both maximum temperature attained and incooling rate

employed.Tempering (not available yet)Reheating hardened steel or

hardened cast iron to some temperaturebelow the eutectoid

temperature for the purpose of decreasing hardnessand increasing

toughness.Stress relievingHeating to a suitable temperature,

holding long enough to reduce residualstresses, and then cooling

slowly enough to minimize the development ofnew residual

stresses.QuenchingA rapid cooling whose purpose is for the control

of microstructure andphase products.Predict hardness, volume fraction metallic structure,

distortion, and carboncontent.Specialized material models for creep, phase transformation,

hardnessand diffusion.Jominy data can be input to predict hardness distribution of the

finalproduct.Modeling of multiple material phases, each with its own elastic,

plastic,thermal, and hardness properties. Resultant mixture

material propertiesdepend upon the percentage of each phase present

at any step in theheat treatment simulation.DEFORM models a complex interaction between deformation,

temperature, and,in the case of heat treatment, transformation and

diffusion. There is couplingbetween all phenomenon, as illustrated

in the figure below. When appropriatemodules are licensed and

activated, these coupling effects include heating due todeformation

work, thermal softening, and temperature controlled

transformation,latent heat of transformation, transformation

plasticity, transformation strains,stress effects on

transformation, and carbon content effects on all

materialproperties. -

10

Figure 1.2.1 : Relationship between various DEFORM modules.

-

11

1.3. Analyzing manufacturing processes with DEFORMDEFORM can be

used to analyze most thermo-mechanical forming processes,and many

heat treatment processes. The general approach is to define

thegeometry and material of the initial work piece in DEFORM, then

sequentiallysimulate each process that is to be applied to the work

piece.The recommended sequence for designing a manufacturing

process usingDEFORMDefine your proposed process Final forged part geometry Material

Tool progressions Starting work piece/billet geometry Processing

temperatures, reheats, etc. Gather required data Material data

Processing condition data Using the DEFORM pre-processor, input the

problem definition for thefirst operation Submit the data for simulation Using the DEFORM

post-processor, review the results Repeat the

preprocess-simulate-review sequence for each operation inthe process If the results are unacceptable, use your

engineering experience andjudgment to modify the process and repeat the simulation

sequence.1.4. Before you beginBefore you begin work on your DEFORM

simulation, spend some time planningthe simulation. Consider the

type of information you hope to gain from theanalysis. Are

temperatures important? What about die fill? Press loads?

Materialdeformation patterns? Ductile fracture of the part? Die

failure? Buckling? Can thepart be modeled as a two dimensional

part, or is a three dimensional simulationnecessary? Having a

definite goal will help you design a simulation which willprovide

the information most vital to understanding your manufacturing

process. -

12

1.5. Geometry representation

Figure 1.5.1 : Axisymmetric and plane strain examples.

DEFORM simulations can be run either as two dimensional (2D) or

threedimensional (3D) models. In general, 2D models are smaller,

easier to set up,and run more quickly than 3D models. Frequently,

the added detail of a 3Dmodel is not worth the additional time

required over a 2D simulation if theprocess can reasonably be

represented in 2D.There are two 2D geometry representations:

axisymmetric and plane strain.Axisymmetric geometries assume that

the geometry of every plane radiating outfrom the centerline is

identical. Plane strain requires that there is no material flowin

the out of plane direction, and that flow in every plane parallel

to the sectionmodeled is identical. Figure 1.5.1 illustrates

axisymmetric and plane strainmodels.Objects that are closely

approximated by axisymmetric or plane strain modelscan also be

modeled in 2D by neglecting minor variations. For example, if

thehead shape is not critical a hex head bolt can be modeled as

axisymmetric bydefining a head radius which maintains constant

volume (radius =0.525*(distance across flats)). A gradually

tapering part such as a turbine bladecan be modeled by modeling

several plane strain sections. -

13

Figure 1.5.2 : Buckling.

Buckling of cylindrical parts is a fully three dimensional

process, and must bemodeled as such if such behavior is expected.

An axisymmetric simulation willnot show buckling; even if it will

occur in the actual process (Figure 1.5.2 ).Partswhich cannot be

simplified to 2D must be modeled as 3D.1.6. The DEFORM systemThe DEFORM system consists of three major

components:1. A pre-processor for creating, assembling, or modifying the

data required toanalyze the simulation, and for generating the

required database file.2. A simulation engine for performing the numerical calculations

required toanalyze the process, and writing the results to the

database file. Thesimulation engine reads the database file,

performs the actual solutioncalculation, and appends the

appropriate solution data to the databasefile. The simulation

engine also works seamlessly with the AutomaticMesh Generation

(AMG) system to generate a new FEM mesh on thework piece whenever

necessary. While the simulation engine is running, itwrites status

information, including any error messages, to the message(.MSG) and

log (.LOG) files.3. A post-processor for reading the database file from the

simulation engineand displaying the results graphically and for

extracting numerical data. -

14

1.7. Pre-processingThe DEFORM preprocessor uses a graphical user

interface to assemble the datarequired to run the simulation. Input

data includesObject descriptionIncludes all data associated with an object,

including geometry, mesh,temperature, material, etc.Material dataIncludes data describing the behavior of the

material under the conditionswhich it will reasonably experience

during deformation.Inter object conditionsDescribes how the objects interact with

each other, including contact, friction,and heat transfer between

objects.Simulation controlsIncludes instructions on the methods DEFORM

should use to solve theproblem, including the conditions of the

processing environment, whatphysical processes should be modeled,

how many discrete time steps shouldbe used to model the process,

etc.Inter material dataDescribes the physical process of one phase

of a material transforming intoother phases of the same material in

a heat treatment process. For example,the transformation of

austenite into pearlite, banite, and martensite.1.8. Creating input dataThere are several ways to enter data

into the DEFORM pre-processor.Depending on the requirements of a

particular problem, a combination of thefollowing methods will

frequently be used.Manual inputThe pre-processor menus contain input fields for

nearly every possible data inputin DEFORM. The user can enter,

view, or edit any of these values. Discussionsof each field are

contained in the reference section of this manual.Keyword file inputMost of the data fields in the DEFORM

pre-processor correspond directly to aDEFORM keyword. Individual

keywords describe very specific information abouta particular

object characteristic, simulation control, material characteristic,

orinter-object relationship. Keyword data can be saved in a keyword

(.KEY) file. A -

15

keyword file is a human readable (ASCII) representation of

DEFORM simulationdata.The typical format of a keyword is:[keyword

name] [keyword parameters][default data][data][data]…A keyword

file may contain a complete simulation data set, or it may contain

onlyone or a few specific keywords.Assembling keyword filesWhen a keyword file is read into the

pre-processor, only the specific data fieldslisted in that keyword

are changed; the remainder is unchanged. Thus, it ispossible to

assemble a complete set of problem data by loading one keyword

filethat contains only data for one object, another keyword file

that contains materialdata, etc.To save specific elements of a

keyword file, it is necessary to save the entire file,then use a

text editor such as Notepad, VI, emacs, or equivalent to

deleteunwanted information. The keyword file load and save features

on the main pre-processor menu load or save an entire data set. To

load partial keyword files,use the Keyword, Load option from the

File menu.Other file inputsVarious data types, particularly part

geometries and material data, can be readfrom appropriate format

files.Modifying problem dataSolution or input step data from any

stored step in a database file can be readinto the pre-processor,

modified, and either appended to an existing database, orwritten to

a new database file.Viewing specific problem dataMost problem data stored in the

database file is accessible in the post-processor.However, certain

specific information such as boundary conditions or

inter-objectcontact conditions is displayed differently in the

pre-processor. When debugginga problem which is not running

properly, it is sometimes useful to use the pre-processor data

display to view this information. -

16

1.9. File systemThe primary data storage structure is the

database file. The database file storesa complete set of simulation

data, including object data, simulation controls,material data, and

inter-object relations, both from the original input, and

fromselected solution steps. The sequence of information storage in

a database file isshown in Figure 1.9.1 . The pre-processor uses an

ASCII format file called thekeyword file to create inputs.Figure 1.9.1 : DEFORM database structure.

Each DEFORM problem has an associated problem ID and should be

created inits own folder or directory. For every problem, the

DEFORM system creates fourtypes of files that are generally

accessible to users:Database (DB) filesThe database file contains the complete

simulation data set for input data andeach saved simulation step.

The information is stored in a compressed, machinereadable format,

and is accessible only through the DEFORM pre- and post-processors.

As the simulation runs, data for each step is written to the end of

thedatabase file. If the step being written is specified as a step

to be saved,information for the next step will be appended after

the current data step. If thestep is not specified to be saved, and

a solution is found for the next step, thedata for the current step

will be overwritten by the data for the next step. -

17

Keyword (KEY) filesKeyword files contain specific problem

definition data which is read by the pre-processor and used to

create an input database file. A keyword file may containa complete

problem definition, or it may contain only specific information

about,for example, a specific object or material. The information

is stored in ASCIIformat, and can be read and edited with any text

editor, such as Notepad, VI, oremacs. A keyword reference is

available which describes the data format foreach keyword.1.10. Running the simulation

Simulation engineThe simulation engine is the program which

actually performs the numericalcalculations to solve the problem.

The simulation engine reads input data fromthe database, then

writes the solution data back out to the database. As it runs,

itcreates two user readable files which track its progress.Log (LOG) filesLog files are created when a simulation is

running. They contain generalinformation on starting and ending

times, remeshings (if any), and may containerror messages if the

simulation stops unexpectedly.Message (MSG) filesMessage files are also created when a

simulation is running. They containdetailed information about the

behavior of the simulation, and may containinformation regarding

why a simulation has stopped.1.11. Post-processor

The postprocessor is used to view simulation data after the

simulation has beenrun. The postprocessor features a graphical user

interface to view geometry, fielddata such as strain, temperature,

and stress, and other simulation data such asdie loads. The

postprocessor can also be used to extract graphic or numericaldata

for use in other applications. -

18

1.12. UnitsDEFORM data may be supplied in any unit system, as

long as all variables areconsistent (i.e., length, force, time, and

temperature measurements are in thesame units, and all derived

units — such as velocity — are derived from the samebase units).

This task can be simplified by using either the British or SI

system forthe default unit system.Figure 1.12.1 : DEFORM unit system.

Note: It is important to select the unit system at the beginning

of the simulation.Once numerical values have been entered in the

pre-processor, the numericalvalues will remain unchanged even if

the unit system designation is changed.The Post-Processor has been equipped with a feature for unit

conversion fordatabase viewing. The user has four options for unit

conversion. If the conversionfactor selected is Default, then the

units are picked up automatically dependingon whether the database

is English or SI. Since there is no conversionnecessary, all the

conversion factors are set to 1.0 in this column. For the casesof

converting English to SI or converting SI to English, the

conversion factors andunits are picked up from the dialog and the

values are converted and displayed inthe post-processor. The fourth

option gives the user the option of viewing thedata from the

database in units that are not English or SI. The user is free

toenter the conversion factors and the units corresponding to the

conversionfactors. There is no user type unit conversion for

temperature, since thetemperature conversion is not a simple

multiplication. -

19

Chapter 2. Pre-Processor

Figure 2.1.0 : The preprocessor of DEFORM-3D. The simulation

controls button ishighlighted with a red square.2.1. Simulation ControlsThe Simulation Controls window can be

found by clicking a button in thePreprocessor ( ). Options defined

under Simulation Controls (See Figure2.1.1 ) control the numerical

behavior of the solution. Main controls details withspecifying the

simulation title, unit system, geometry type, etc. Stopping and

stepcontrols are used to specify the time step, the total number of

steps and thecriteria used to terminate the simulation. Processing

conditions like theenvironment temperature, convection coefficient

can be specified underProcessing conditions. Certain advanced

features are explained in the Advancedcontrols section. -

20

Figure 2.1.1 : Simulation Controls window.

2.1.1. Main controls

Simulation title (TITLE)The simulation title allows you to title

the problem (up to 80 characters) forreference purposes.Operation name (SIMNAM)The operation name allows you to title

the specific operation (up to 80characters) for reference

purposes.Units (UNIT)The DEFORM unit system can be defined as

English or Metric (SI). Allinformation in DEFORM should be

expressed in consistent units. The unit systemshould be selected at

the beginning of the problem setup procedure, and shouldnot be

changed during a simulation or after an operation. -

21

Figure 2.1.2 : DEFORM unit system.

Type

The five different types of simulations that can be run are:

Lagrangian Incremental: To be used for all the conventional

forming, heattransfer and heat-treat applications. Transient phase

of the processes likerolling, machining, extrusion, drawing cogging

etc. also can be modeled inthis general framework.ALE Rolling: ALE model for rolling process can be generated

using theShape Rolling template. When the model is generated using

thistemplate, automatically generates the necessary boundary

conditions forthe entry surface for the billet (indicated in the

interface as the Beginningsurface, nodes are assigned BCCDEF=4),

and the exit surface ( indicatedin the interface as Free surface,

nodes are assigned BCCDEF=5).Template automatically sets the

analysis type as ALE Rolling. When therolling model is setup using

the regular pre-processor, user needs to setthis analysis type and

proper boundary conditions to be able to run theALE model for

rolling.Steady-State machining: 3D machining model for turning

applications canbe generated using the Machining Template in which

the initial model canbe set up for Lagrangian Incremental run. When

sufficient chip has formedthe template can be used to generate an

additional operation to switch theanalysis mode to Steady State. In

this stage template can be used togenerate the required boundary

conditions for the steady state run, whichincludes defining end

surface of the chip (indicated as free surface, withBCCDEF code set

as 5 for those nodes). Template automatically sets theanalysis type

as Steady-State Machining. When the machining model issetup using

the regular pre-processor, user needs to set this analysis typeand

proper free surface and thermal boundary conditions to be able to

runthe Steady State model for machining. -

22

Ring Rolling: From 3DV61, simulation engine has been enhanced

tohandle the non isothermal modeling of ring rolling process.

Thisdevelopment includes a special ALE technique that does not

depend onany expensive computing resources, nor involves very long

modelingtimes.Steady-State extrusion: Provided for future implementation:

(CurrentEulerian process modeling capability for extrusion, which

is underdevelopment can be activated using a special data file

called ALE.DAT.Please contact SFTC for additional information.)Simulation modes (SMODE, TRANS)DEFORM features a group of

simulation modes that may be turned on or offindividually, or used

in various combinations.Heat transferSimulates thermal effects within the simulation,

including heat transferbetween objects and the environment, and

heat generation due todeformation or phase transformation, where

applicable.DeformationSimulates deformation due to mechanical, thermal, or

phase transformationeffects.TransformationSimulates transformation between phases due to

thermomechanical and timeeffects.DiffusionSimulates diffusion of carbon atoms within the

material, due to carboncontent gradients.GrainSimulates grain size calculation and recrystallization

calculations.HeatingSimulates heat generation due to resistance or induction

heating. Thisfeature is not activated in the current release. -

23

For backward compatibility with old keywords and databases,

before version3.0, the keyword SMODE (old style isothermal,

non-isothermal, heat transfer)is read and the corresponding keyword

TRANS mode switches are set in thepre-processor.Operation number (CURSIM)Allows the specification of a new

operation number for each simulation in thedatabase. If operations

numbers are specified, the post-processor displays eachoperation

with its number in the step list.Mesh number (MESHNO)This variable records the current mesh based

on the number of remeshings thatoccur between the initial mesh and

the current mesh. This variable should not bechanged.Figure 2.1.3 : Step Controls.

2.1.2. Step ControlsThe DEFORM system solves time dependent

non-linear problems by generatinga series of FEM solutions at

discrete time increments. At each time increment,the velocities,

temperatures, and other key variables of each node in the

finiteelement mesh are determined based on boundary conditions,

thermomechanicalproperties of the work piece materials and possibly

solutions at previous steps.Other state variables are derived from

these key values, and updated for eachtime increment. The length of

this time step, and number of steps simulated, aredetermined based

on the information specified in the step controls menu (See -

24

Figure 2.1.3 ).Starting step number (NSTART)

If a new database is written, the specified step number will be

the first step in thedatabase. If data is written to an existing

database, the preprocessor data will beappended to this database in

proper numerical order, and any steps after the onespecified will

be overwritten.The negative (-n) flag on the step number indicates

that the step was written tothe database by the pre-processor

(either by manual generation of a databasestep or by an automatic

remesh), not by the simulation engine.Note: All pre-processor

generated steps should have a negative step numberNumber of simulation steps (NSTEP)

The number of simulation steps parameter defines the number of

steps to runfrom the starting step number. The simulation will stop

after this number ofsimulation steps will have run, if another

stopping control is triggered to stop thesimulation or if the

simulation runs into a problem. For example, if the startingstep

number is -35 (NSTART), and 30 steps (NSTEP) are specified,

thesimulation will stop after the 65th step, unless another

stopping control istriggered first.Step increment to save (STPINC)

The step increment to save in the database controls the number

of steps that thesystem will save in the database. When a

simulation runs, every step must becomputed, but does not

necessarily need to be saved in the database. Storingmore steps

will preserve more information about the process; consequently it

willrequire more storage space.Primary die (PDIE)

The primary die is the object for which many stopping and

stepping criteria aredefined. For example, stopping distance based

on primary die stroke. When thestroke of the object defined as the

primary die reaches the value for primary diedisplacement, the

simulation will be stopped whether or not more steps werespecified.

The Step By Stroke feature determines step size based on

themovement of the primary die.The primary die is usually assigned

to the object most closely controlled by theforging machinery. For

example, the die attached to the ram of a mechanicalpress would be

designated as the primary object. -

25

Step increment control (DSMAX/DTMAX)

Solution step size can be controlled by time step or by

displacement of theprimary die. If stroke per step is specified,

the primary die will move the specifiedamount in each time step.

The total movement of the primary die will be thedisplacement per

step multiplied by the total number of steps. If time per step

isspecified, the time interval per step will be used. The die

displacement per stepwill be the time step times the die

velocity.From 3DV61, the definition of step increment control has

been enhanced toinclude both the time and stroke dependent step

functions. This means, step size(both time per step and stroke per

step) can now be defined as a function of timeor stroke. This

functionality enables finer resolution of saved model

information,where it is desired. (Typically towards the end of the

stroke, where steepchanges of die load and cavity filling or flash

formation can take place).Stroke per step is frequently more

intuitive. However, time per step must bespecified for any problem

in which there is no die movement (such as heattransfer), or for

any problem where force control is used.Selecting time step and

number of stepsProper time step selection is important. Too large a

time step can causeinaccuracy in the solution, rapid mesh

distortion or convergence problems. Toosmall a time step can lead

to unnecessarily long solution times. The followingsection provides

some guidelines for selecting time steps.The maximum displacement

for any node should not exceed about 1/3 the lengthof its element

edge length in one step. For flow around a tight corner,

flashforming, or similar highly localized deformations, time steps

may need to bedefined to give a node movement of as small as 1/10

or the element edge length.Thus, for a finer mesh, smaller steps

are required than for a coarser mesh. Thisprevents the mesh from

becoming overly distorted in a single time step.The time step can

be determined by the following method:1. Using the measurement tool, measure one of the smaller

elements in thedeforming object (this must be done after a mesh has

been generated)2. Estimate the maximum velocity of any region of the work piece

(for mostproblems, this will be the die velocity. For extrusion

problems it will be thedie velocity times the extrusion ratio) If

some steps have already be run,display object velocity under

Object->Nodes (use the «eye» icon to displaya velocity vector

plot and maximum and minimum values).3. Divide the result of 1 by the result of 2, and take about 1/3

of this value asthe time step. This is a rough estimate, so extreme

accuracy is not critical.4. The number of steps is given by where n is the number of

steps, x is thetotal movement of the primary die, V is the primary

die velocity, and is thetime increment per step. -

26

Refer also to the Polygon Length Sub-Step feature under Advanced

StepControlsIf there is insufficient information available to

calculate the total number of steps,three alternatives are

available:1. A general guideline of 1% to 3% height reduction per step can

be used.2. Specify an arbitrarily large number of steps, and use an

alternativestopping control, such as time or total die stroke.3. Make a

good estimate of the number of steps required for the given

stepsize, and then specify about 120% of this value. Allow the

simulation toovershoot the target, and then use a step near, but

not at the end as afinal solution.2.1.3. Advanced Step Controls

This menu gives more options for special simulations where

precision control oftime step size is required (See Figure 2.1.4

and Figure 2.1.5 ).Figure 2.1.4 : Advanced stepping menu 1.

Step definition (STPDEF)There are three modes for defining

stepsUser In user defined steps mode, the steps correspond to the

NSTEPvalue. This is the default which does not have to be changed

in almost allcases.System In the system defined steps mode each sub step is saved

to thedatabase and is treated as a step. This option is primarily

used fordebugging purposes. -

27

Temperature In temperature based sub stepping, the DTPMAX

settingscontrol the time stepping. The purpose for these controls

is to specify thetime stepping of a simulation that is driven by

thermal-induceddeformation.Strain per step (DEMAX)The maximum element strain increment

limits the amount of strain that canaccumulate in any individual

element during one time step. If a non-zero value isassigned to

DEMAX, a new sub step will be initiated when the strain increment

inany element reaches the value of DEMAX.Contact Time (DTSUB)Contact time controls whether or not sub

stepping is performed when nodescontact a master surface. By

default (DTSUB = 0), if a node contacts a mastersurface a fraction

of the way through a time step, the time step is subdivided,

andthat step is run again at the fraction of the time increment.

This will place thenode on the surface at the end of the time step.

For 3D problems with a largenumber of nodes contacting master

surfaces, this can cause huge increases inexecution time.If DTSUB

is set to 1, contact time sub stepping is disabled. Nodes will be

allowedto penetrate the master surface, but then will be

artificially moved back to surfaceat the end of the time step. This

will allow significantly faster execution time.However, if the

defined time step is too large, some volume loss and meshdistortion

may occur.In general, it is recommended that DTSUB be set to 1, and

that the time stepguidelines described above be followed carefully.

Use of polygon length substepping, DPLEN, will also control volume

loss and mesh distortion, withoutsevere execution time

increases.Polygon length substep (DPLEN)Polygon length sub stepping places

an upper limit on the absolute distance asurface node can move in a

given time step. The largest distance a given nodecan move is

defined byu

dplenLt

))((max =

Where,L = the distance from a given node to the nearest adjacent

surface on thesame objectdplen = the coefficient controlling the

relative maximum time step allowedu = the magnitude of the velocity

of the nodetmax = the maximum time step size allowed -

28

Legal values of DPLEN are from 0 to 1. A value of 0 will disable

sub stepping.Recommended values are 0.2 to 0.5, with 0.2 being more

conservative, andhence slower, and 0.49 being more aggressive, and

faster, but less accurate.Values larger than 0.5 can be used, but

may allow unacceptable meshdegeneration.Figure 2.1.5 : Advanced stepping menu 2.

Temperature change per step (DTPMAX)The maximum temperature

change increment limits the amount that thetemperature of any node

can change during one time step. If a non-zero value isassigned, a

new sub step will be initiated when the temperature change at

anynode reaches the value of DTPMAX. The maximum/minimum time step

are thelargest and smallest time step allowable with the

temperature based sub-stepping.Maximum Sliding ErrorThis stepping control is not generally

recommended. Please contact SFTC formore information. -

29

Figure 2.1.6 : Process parameters for stopping a simulation.

2.1.4. Stopping Controls

The stopping parameters determine the process time at which the

simulationterminates. A simulation can be terminated based on the

maximum number oftime steps simulated; the maximum accumulated

elemental strain, the maximumprocess time, or maximum stroke,

minimum velocity, or maximum load of theprimary object. A

simulation will be stopped when the condition of any of thestopping

parameters are met. If a zero value is assigned to any of the

terminationparameters other than number of steps (NSTEP), the

parameter will not be used.If no other stopping parameters are

specified, the simulation will run until it hasutilized all of the

specified steps. (See Figure 2.1.6 )Process Duration (TMAX)Terminates a simulation when the global

process time reaches the valuespecified.Primary Die Displacement (SMAX)Terminates a simulation when the

total displacement of the primary die reachesthe specified value.

The stroke value for the object is specified in the Object,Movement

menu.Minimum velocity of Primary Die (VMIN)Terminates a simulation

when the X or Y component of the primary die velocityreaches the X

or Y values of the VMIN. This parameter is typically used when

theprimary object movement is under load control, or when the

SPDLMT parameteris enforced for a hydraulic press. -

30

Maximum load of Primary Die (LMAX)Terminates a simulation when

the X or Y load component of the primary diereaches the X or Y

value of LMAX. Typically used when the movement control ofthe

primary object is velocity or user specified.Maximum strain in any Element (EMAX)Terminates a simulation when

the accumulated strain of any element reaches thespecified

valueFigure 2.1.7 : Stopping distance based on die distance.

Stopping distance (MDSOBJ)Terminates a simulation when the

distance between reference points on twoobjects reaches the

specified distance. Stopping distance must be used inconjunction

with the reference point (REFPOS) definition Die Distance

window(See Figure 2.1.7 ).Stopping Plane (REFPOS) Typically used in

the models like transient rolling process, user can define aplane

in space, and have the simulation terminate once the work

piececompletely crosses this plane. (See Figure 2.1.8 ) -

31

Figure 2.1.8 : Stopping distance based on stopping plane.

2.1.5. Remesh CriteriaPlease refer to the section on meshing for

a description of this window.2.1.6. Iteration ControlsThe iteration controls specify criteria

the FEM solver uses to find a solution ateach step of the problem

simulation. For most problems, the default valuesshould be

acceptable. It may be necessary to change the values if

non-convergence occurs (See Figure 2.1.9 ). -

32

Figure 2.1.9 : Iteration controls for the deformation

solver.Deformation solver (SOLMTD)The sparse solver is a direct

solution that makes use of the sparseness of FEMformulation to

improve solution speed. The conjugate-gradient solver tries tosolve

the FEM problem by iteratively approximating to the solution. For

certainproblems, this solver offers tremendous advantages over the

Sparse solver.The advantages of the iterative solver include:

Up to 5:1 improvements in overall solving time, particularly in

very largeproblemsAbility to handle very large numbers of elements in reasonable

time andwith reasonable memory demands. (The largest problem to

date is380,000 elements, using 1GB of RAM).Much smaller memory requirements for smaller problems — makes

3Dpractical on inexpensive computers or laptops.Limitations:

In certain situations, convergence may be slower, or the

simulation maynot converge, when the sparse solver will converge.

This is particularly aproblem for simulations with large «rigid

body motion» such as occurswhen a part is settling into a die,

undergoing light deformation, or bending.When the conjugate-gradient solver cannot successfully converge

toward thesolution, DEFORM-3D will fall back to the sparse solver.

From 3DV61, a newsolver GMRES has been added to the available

solvers, to take advantage ofmultiple CPU environments. The GMRES

option can only be used in multi CPUmode. -

33

When to use the iterative solverThe solver is generally very

good for problems with a lot of contact with the dies.If a work

piece is not well positioned in the dies, or if it will be sliding

a bit beforeit starts deforming, you should start the simulation

with the sparse solver. Oncethere is some substantial deformation

in the work piece, stop the simulation, loadthe final step into the

preprocessor, change to «Conjugate Gradient» and «Direct»,and write

the database.Keep an eye on the message file for the first few

steps. The first step may be abit slow converging. If the second

step is still struggling to converge, or if thesimulation stops,

you may need to switch back to the sparse solver for a fewmore

steps.In general, simulations in which you might expect convergence

problems usingthe Sparse solver are not well suited for Conjugate

Gradient. Most problems,particularly thin parts or flash parts,

will do well after the first 20-30 steps, if notsooner.Figure 2.1.10 : Plot of relative time versus elements for

different solvers for elasticobjects.Figure 2.1.11 : Plot of relative memory versus elements for

different solvers for elasticobjects. -

34

Iteration methods (ITRMTH)An iteration method is the manner in

which the simulation solution is updated (oriterated upon) to try

to approach the converged step solution.Newton-Raphson The Newton-Raphson method is recommended formost

problems because it generally converges in fewer iterations than

theother available methods. However, solutions are more likely to

fail toconverge with this method than with other methods.Direct The direct method is more likely to converge than

Newton-Raphson, but will generally require more iteration to do so.

In the case ofPorous materials, the direct method is the only

method currently available..

Solver recommendations for 3D

NR : Newton Raphson iterationsDI : Direct iterationsSP : Sparse

SolverCG : Conjugate Gradient SolverSTD : Elasto-Plastic Standard

FormulationsMIX : Elasto-Plastic Mixed FormulationsCC : Conformal

Coupling (CC) for Contact constraintsPEN : Penalty based contact

constraintsModel Data Recommended Can be used Should notbe used

General Forming modelswithPlastic objects(well constrained

models)CG, DI NR,SP

General Forming with Elasto-Plastic objects

SP, NR,STD DI

Spring Loaded Dies SP CG

Force Controlled Dies SP CG

Heat Treatment with Tet.Mesh Elasto-Plastic

SP, NR, MIX CG,NR

Heat Treatment with BrickMesh Elasto-Plastic

SP, NR CG,NR

Multiple Deforming ObjectsPlastic + Plastic (Large

deformation)SP,DI,CC CG

Multiple Deforming Objects SP,NR,PEN DI

-

35

Plastic + Plastic (Smalldeformation)

Multiple Deforming ObjectsElasto-Plastic objects

SP, NR, PEN DI,CC

Die Stress modelsElastic + Elastic Objects

SP, NR CG

Rotational Symmetry models(Elasto-Plastic objects)

SP,NR,PEN CG,CC

Rotational Symmetry models(plastic objects)

SP,DI,CC CG,NR

Pure Heat Transfer models CG NR

Convergence error limits (CVGERR)A deformation iteration is

assumed to have converged when the velocity andforce error limits

have been satisfied. This means that the change in both thenodal

velocity norm and the nodal force norm is below the value specified

here.The error norm values for each iteration step are displayed in

the message file.If the message file shows that the force or

velocity error norms are getting small,but not dropping below the

error limits, the simulation may be continued byincreasing the

appropriate error limit to the smallest value in the message

file.This will decrease the solution accuracy, so the simulation

should be allowed torun a few steps, then the values should be

reduced again. When doing this,extreme care should be exercised.

For die stress or press load calculationswhere extremely accurate

force or load values are required, the load accuracymay be improved

by decreasing the force error limit. This will increase

simulationtime, but give more accurate results.Note: It should be noted that the accuracy of the flow stress

data will have greatimpact on the accuracy of die stress and press

load predictions.Bandwidth optimization (DEFBWD, TMPBWD)Bandwidth optimization

improves solution time by optimizing the structure of thematrix

equation being solved. It should be used for almost all

problems. -

36

Figure 2.1.12 : Temperature iteration settings.

Temperature solver (SOLMTT)The sparse solver is a direct

solution that makes use of the sparseness of FEMformulation to

solve for the temperature. Currently, this is the only

solveravailable for solving thermal problems.Initial guess (INIGES)Initial guess generation improves the

convergence behavior of the first step ofthe solution. It should be

used for almost all problems.Bandwidth optimization (DEFBWD, TMPBWD)Bandwidth optimization

improves solution time by optimizing the structure of thematrix

equation being solved. It should be used for almost all

problems. -

37

2.1.7. Processing ConditionsThe processing conditions menu

contains information about the processenvironment, and constants

related to general solution behavior.Figure 2.1.13 : Heat transfer processing conditions.

Environment temperature (ENVTMP)Environment temperature is used

in radiation and convection heat transfercalculations and

represents the temperature of the area in which the modeledprocess

is taking place. The environment temperature may be specified as

aconstant or as a function of time. Heat transfer to this

temperature is consideredto occur from any nodes not in contact

with another object. (unless heatexchange windows are used ). No

radiation view factors are accounted for unlessthis option is

activated. Adding the file DEF_VIEW.DAT to the directory wherethe

simulation is run will activate this. The contents of the file are

unimportant.Convection coefficient (CNVCOF)The convection coefficient is

required for convection heat transfer calculations.The convection

coefficient may be specified as a constant or as a function

oftemperature. -

38

Figure 2.1.14 : Diffusion processing conditions.

Environment atom content (ENVATM) [MIC]The percentage atom

content of the dominant atom (usually carbon) for

diffusioncalculations.Reaction rate coefficient (ACVCOF) [DIF]The surface reaction

rate with the atmospheric atom content for

diffusioncalculations.Figure 2.1.15 : Advanced constants.

-

39

Interface penalty constant (PENINF)A large positive number used

to penalize the penetration velocity of a nodethrough a master

surface. The default value is adequate for most simulations.

Itshould be at least two to three orders higher than the volume

penalty constant(PENVOL). For objects of very small size (e.g.

fasteners), it is recommended toreduce this number on order of

magnitude or two to improve convergence. Thiswill only aid

convergence if the sparse solver is used.Mechanical to heat conversion (UNTE2F)A constant coefficient to

relate units of heat energy(eg BTU) to mechanicalenergy (eg

klb-in). Appropriate constant values are automatically set for

Englishand SI units.Time integration factor (TINTGF)The time integration factor is

the forward integration coefficient for temperatureintegration over

time. Its value should be between 0.0 and 1.0. The value of 0.75is

adequate for most simulations.Boltzman constant (BLZMAN)The Boltzman constant is required for

radiation heat transfer calculations. Defaultvalues for English and

SI are set automatically. In radiation heat calculations thenodal

temperature will be automatically converted to absolute

temperature(Rankine, Kelvin) based on the selected English or SI

units.2.1.8. Advanced Controls

Figure 2.1.16 : Advanced variables.

-

40

Current Global Time/Current Local Time (TNOW)These values

specify the global process time and the local process time.

Theglobal time is the time since the beginning of the problem, and

should never bereset. Local time is a parameter that can be reset

by the user. The global timeshould not be reset during a simulation

as the post-processor uses this time formany post-processing

operations. Below the local and global time definitions is

aselector box that determines which time is to be used for time

dependentfunctions such as movement controls. The default is global

time; however, thetime dependent functions can also be made a

function of local time.Primary Work pieceThis parameter allows the user to specify the

work piece as an object that mustnot possess rigid body motion. If

the body does not deform, the simulation willstop. One purpose of

this function is to prevent a rolling simulation fromcontinuing

past the rolled length of material.Use original additive rule for transformation kineticsWe have

improved the transformation kinetics rule from version 6.0. With

thenew version, multiple transformations can occur at the same time

andtemperature for a given material. If the user does not want to

use this new ruleand wants to use the previous one, checking this

box will allow this.Error Tolerances

Geometry error (GEOERR)This value is an estimate of the error

between discretized objects. The defaultvalue for this is

sufficient for most of the general applications. (see Figure

2.1.17Figure 2.1.17 : Error tolerances window.

-

41

User defined variables (USRDEF)User defined variables are 80

character string variables which are passed to userdefined

subroutines. Refer to the chapter on User Routines for more

informationon how to use these variables. (See Figure 2.1.18 )Figure 2.1.18 : User defined values

Output ControlStarting from version 6.0, the simulation control

options are further enhancedwith two important features.1. The first among these is to include a wide selection of

strain components thatcan be stored by the user depending upon the

analysis and object type. Theseoptions for a typical elasto-plastic

object enable user to store plastic, elastic andtotal strains. For

non-isothermal models with elasto-plastic objects

additionallythermal volumetric strains can also be stored for each

stored step of thesimulation. When transformation is turned on, the

strain components that areproduced due to phase transformation can

be stored as well. Once set in thePre-Processor, (Figure 2.1.19 )

each of these strain components are available inpost processing for

point tracking, contour plots and other normal display

options(Figure 2.1.20 ).2. The second option in the output control

that is available to the user is intendedto improve the state

variable representation in the analysis domain and minimizethe

interpolation error involved in the remeshing procedures. Such

representationcan also better maintain the local gradients of the

state variables compared tothe existing the element based

representation. In the current version, the user -

42

can choose to represent damage, strain and stress state as

Element+Nodal data.This means in addition to the currently