Блог

-

Вы здесь:

- О компании

- Блог

- Десять основных шагов расчета динамических задач в явной постановке. Часть вторая.

В предыдущей статье я изложил первые шесть шагов, необходимых для создания надежных, быстрых и точных моделей для динамических расчётов в явной постановке (Explicit Dynamics). В этой статье я представлю следующие четыре шага. Хочу обратить ваше внимание на то, что описанные шаги являются довольно общими и применимы практически ко всем динамическим расчётам в явной постановке. Однако в особых случаях, возможно, будут необходимы дополнительные настройки. Например, для расчёта взрывного процесса может быть задана расчётная область в постановке Эйлера для моделирования непосредственно взрыва, а затем включены специальные механизмы связанных расчётов для моделирования взаимодействия детонационных газов и твердых тел.

Пошаговое изложение ключевых аспектов создания моделей для расчёта динамических задач в явной постановке (модули Explicit Dynamics):

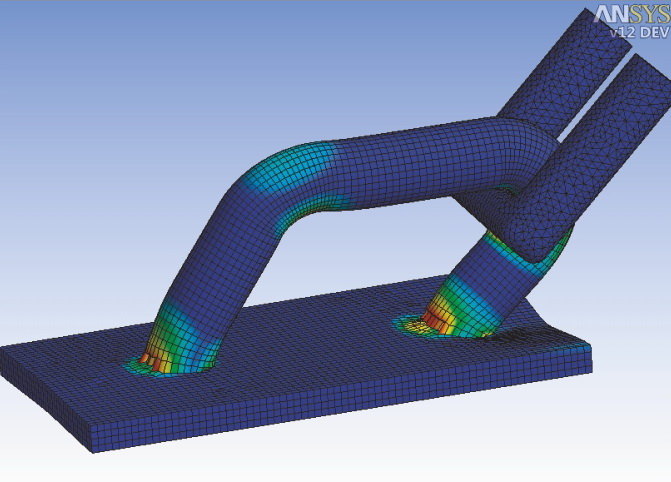

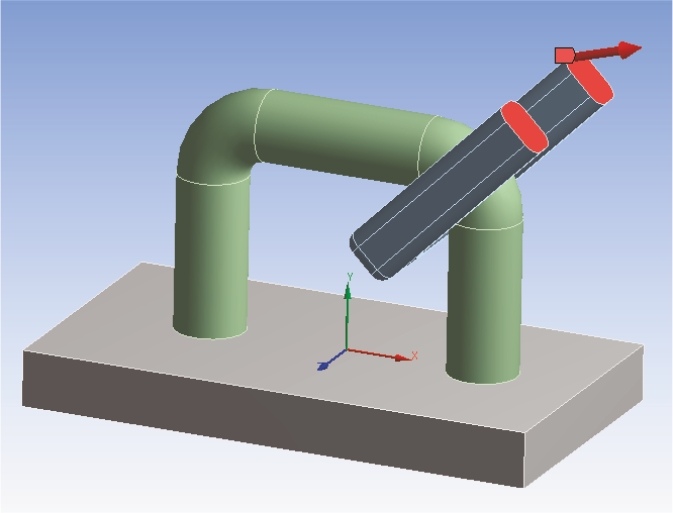

7. Создайте сетку.

- Создайте сетку с относительно равномерным распределением размеров элементов. Зоны модели с очень мелкой сеткой приведут к увеличению времени расчета за счет уменьшения потребного шага по времени. На рисунке 1, приведенном выше, показано сравнение предпочтительных сеток для моделей в явной (explicit) и неявной (implicit) постановках расчёта. В динамическом расчёте высокоэнергетических процессов за счёт перемещения и взаимодействия волн колебаний максимальные напряжения могут возникать практически в любом месте, так что для расчёта в явной постановке наличие мелкой сетки в местах скруглений не представляет большой важности.

Некоторые инструменты создания сетки в ANSYS Workbench/LS-Dyna, такие как виртуальная топология (virtual topology) и построение сетки с упрощением геометрии (defeaturing), предоставляют возможности для создания сетки без жесткой привязки к геометрическим элементам. Это значит, что сетка не должна совпадать с границами геометрических поверхностей. Ниже на рисунке 2 показан пример, где созданная по умолчанию сетка содержит очень мелкие элементы на узких поверхностях, присутствующих в показанной слева геометрической модели. Относительно равномерная сетка (нижний рисунок справа) значительно предпочтительнее, поскольку она позволяет существенно сократить время расчета за счет увеличения шага по времени. - Используйте как можно больше гексагональных элементов. Элементы в форме тетраэдров не только существенно увеличивают размер модели, но и, как правило, значительно уменьшают потребный шаг по времени.

8. Задайте начальные условия, нагрузки и граничные условия.

- Задайте начальные условия, такие как начальные скорости поступательного и вращательного движения.

- Используйте гладкие кривые изменения нагрузки (например, синусоидальный закон) – это помогает сгладить ударные эффекты.

- Перед запуском решения выведите список и/или выведите графики изменения нагрузок для проверки.

- Для квазистатических расчётов используйте большую скорость и редуцированный расчёт (reduced transient analysis), чтобы уменьшить время расчета. Более подробную информацию о квазистатическом расчёте вы можете найти в моей статье под названием «Чем может помочь решатель для задач в явной постановке в сложных нелинейных статических расчётах?» (How Can Explicit Solvers Help With Stubborn Nonlinear Statics Models?)

9. Создайте и отобразите контактные взаимодействия.

- a) Для оболочечных моделей предпочтительнее выбирать те типы контактов, которые позволяют определять статус контакта на обеих сторонах оболочки. К ним относятся автоматические типы контактов в LS-Dyna.

- b) Не забудьте включить в контактные пары все поверхности, по которым может возникнуть контакт.

- c) При необходимости используйте тип контакта, который поддерживает контактное взаимодействие при самокасании поверхности. Это может понадобиться при смятии конструкции, что часто возникает при расчёте удара автомобиля или моделировании технологических процессов обработки металлов давлением. На рисунке 3 показан пример такого деформирования – сжатие швеллера.

- d) По возможности избегайте начального проникновения. Оно может создавать ложные напряжения, погрешности в определении энергии, а также приводить к нежелательным искажениям геометрии оболочки.

10. Задайте настройки решателя и запустите расчет.

- Укажите время переходного процесса.

- Укажите периодичность вывода результатов. Необходимо использовать достаточное количество точек для того, чтобы были зафиксированы результаты в важные моменты времени, но излишне большое количество точек может привести к переизбытку данных.

По возможности получайте данные с мелким шагом по времени только для совокупности узлов и элементов в важных и интересующих вас зонах. - Запросите вывод таких результатов, как энергия в модели в целом и в каждой детали, силы реакции и силы контактного взаимодействия. Вывод результатов по энергиям является критически важным с точки зрения проверки ошибок. Например, если энергия, соответствующая нефизичному характеру деформирования типа «песочные часы» (hourglass energy), очень высока, то есть на это деформирование уходит существенная доля общей энергии, это говорит о том, что необходимо уделить особое внимание специальным моделям для устранения этого эффекта. Кроме того, сумма первоначальной энергии и работы внешних сил всегда должна быть примерно равна полной энергии системы в любой момент времени.

- Разумно используйте массовое масштабирование (mass scaling). Массовое масштабирование – это надежный и проверенный метод для сокращения времени квазистатических расчётов, где скорость процесса мала, а кинетическая энергия пренебрежима в сравнении с энергией деформирования. При грамотном применении в определенных случаях его также можно применять для динамических расчетов. Больше информации о массовом масштабировании вы можете найти в моей статье под названием «Что такое массовое масштабирование, и когда его уместно применять для динамических расчётов в явной постановке?» (What is Mass Scaling and When is it Appropriate in Explicit Dynamics Analysis?)

Теперь у вас есть полный список шагов, необходимых для создания надежных, быстрых и точных моделей для динамических расчётов в явной постановке (Explicit Dynamics). Я попытался представить дополнительные подробности для шагов, которые специфичны для расчётов явной динамики. Надеюсь, это описание поможет для первоначального знакомства или для развития ваших навыков в этом типе расчётов.

Источник: https://caeai.com/blog/top-ten-list-explicit-dynamics-analysis-part-2

Автор: Steven Hale

Продукты

Услуги

Новости

Блог

What is the Explicit Method?

In the last 15 years, Ansys has gone from offering a single explicit dynamics workflow, using Mechanical APDL with a third-party solver and postprocessor, to offering several unique and versatile solutions. These days Ansys customers can leverage two distinct solvers and multiple pre and post processors in various combinations in order to best meet their needs. However, before a user can determine the right explicit solution for themselves, they must first understand what the term “explicit dynamics” means and what sort of problems that methodology is meant to tackle.

Implicit vs. Explicit Methods in FEA

Traditionally, finite element analysis of a transient structural system is carried out using an implicit solutions method; this approach involves two key principles:

- The assembly of the mass, stiffness, and damping matrices to describe the inherent factors relating to the motion of the structure.

- The approximated solution an ordinary differential equation describing that motion:

For those inclined to stare blankly at the first sign of math, this equation of motion essentially shows that any external force acting on an object will result in displacement (u vector), velocity (v vector) and acceleration (a vector) of that object. The magnitude of that motion will be inversely related to the stiffness in the system (K matrix), the amount of damping (C matrix), and the mass of the system (M matrix). You can think of these matrices as how springy or elastic the material in use is, how much kinetic energy loss occurs due to heat or sound, and how much resistance to a change in velocity exists respectively. Things get further complicated by the fact that displacement, velocity, and acceleration are all interrelated in a way that makes these equations very difficult to solve directly.

The other significant concept here is the use of matrices to define behavior of a complex system. Since FEA in general involves a component or assembly of components that are broken down into many nodes with many more connections to adjacent nodes, the equations of motion for each node starts to get complicated very quickly. Matrices are a way to describe these complex systems in an organized way that allows a solver to take advantage of certain operations possible in linear algebra.

Consider this 1-dimensional system of springs and nodes. Note that we are only considering the elastic (displacement-related) portion of the motion equations and not inertial (acceleration) or damping (velocity):

The total force acting on, and displacement of each node is going to be related to the relative displacement of the adjacent node or nodes and the stiffness of the springs connecting them. Using a stiffness matrix, we can describe the behavior of the entire system mathematically:

This might look somewhat familiar if you look at the first part of that motion-equation we looked at earlier. In this case, we’re looking at the global stiffness matrix of a simple system as opposed to the matrix of a single node or object. The stiffness between nodes in a finite element model can be thought of as being very similar to the springs’ stiffness in our simple system, and the mass of the system and damping properties can be thought of very similarly to the stiffness in terms of matrix assembly.

So, where are we going with all this? Well, FEA software uses a linear algebraic approach to simplify these matrices before attempting to solve the full equations of motion of the system. In fact, much of the CPU time consumed during the solve process is taken up by this matrix “decomposition” as it is known. Additionally, because the full transient equations of motion can’t easily be solved directly from one point in time to the next, a set of values known as Newmark’s Parameters are used to approximate an incremental change of displacement, velocity, and acceleration between time-steps. The most common method of leveraging these parameters is known as the Newton-Raphson iteration, and involves an iterative approach to solving for the force on any node in the system.

It works like this: the starting position, velocity, and acceleration of the system are known, so the matrices at this state act as our starting point. For the first time increment, a set of matrices modified using the Newmark’s Parameters are formulated and a test force is applied at each node. This test force will result in a new set of positions, velocities, and accelerations at each nodal location. This newly calculated equilibrium state will also result in a new set of calculated forces at each node, and this calculated force can then be compared to the test force. Usually the first iteration will not result in values that fall within a range resulting in an acceptable residual value, so the matrices will be further modified from this first attempt and the process will repeat. This same process repeats until the test force and the calculated force are close enough to be considered converged.

That, in a nutshell, is how the implicit transient method works. In contrast, explicit dynamics takes a different approach to solving motion equations altogether. Instead of using a test force value and incrementally adjusting the system matrices until that test force value matches the resultant equilibrium forces, the explicit approach involves simply integrating the acceleration and velocity terms in the equations over a short period. This results in equations that are defined in terms of displacement alone, meaning they can be solved without the need for convergence toward a solution! Not only that, but this approach also bypasses the need for matrix assembly and decomposition as well, meaning no need for the solver to spend all that time building and simplifying a matrix.

By getting rid of these two often onerous steps, the explicit method allows users to tackle highly complex and nonlinear problems that would otherwise be very difficult to converge (and in many cases it can do so much, much faster). In fact, the Explicit method can be used for some very sophisticated analyses, such as simulating breakage (elements being deleted from the simulation) based on a limit strain value, because the solution at a timestep does not need to converge based on the state of the system at a previous step.

You might be thinking, “Great! Clearly the explicit method is superior. Why wouldn’t we use that approach for everything?” Well, here is the rub: explicit study requires that the analysis be both time-dependent (or transient), and that a minimum time step size be used. The explicit dynamic EOMs are probably not worth showing in their entirety, but one particular term is the issue here:

That innocuous-looking little term might look familiar if you know the equation for the natural frequency of an oscillator:

The significance here is that if the timestep of the explicit analysis, identified here as Δt_i, is longer than the shortest period corresponding to the natural frequencies of the system divided by pi, the motion equation becomes unstable and can’t be solved.

The natural frequencies of the system are sensitive to numerous factors, most significant here are that this period for the natural frequency will decrease with:

- Increasing material stiffness

- Decreasing material density or decreasing mass

- Decreasing size of the SMALLEST element in the entire model

Therefore, the stiffer, more massive, and smaller that smallest element in the model is, the shorter our timestep needs to be to get a solution. And these timesteps can be a tiny fraction of a millionth of a second in many cases! Therefore, even though the Explicit method is a more direct way of solving the equations involved, depending on the problem involved, it might still be more efficient to approach with an implicit solver because of the numerous timesteps necessary for an explicit solution.

Here’s the Bottom Line

The Implicit approach is still a robust and reliable method for solving FEA problems, and usually is the more time and effort-friendly approach for static cases or those that don’t involve much nonlinearity. However, whenever a simulation involves very rapid changes to the state of the model, involves large amounts of deformation or material nonlinearity, or deletion of elements based on material failure, the explicit method excels.

High/Hyper-Velocity Impact and Material Failure

Foam and other Highly Non-linear Material

Blast/Explosion/Deflagration

Explicit dynamics can also be very useful for simulating snap-through behavior, metal forming operations, and any number of other events that might otherwise be impossible with the implicit approach. In part 2, we will explore the Ansys Explicit Dynamics portfolio and discuss how each software stacks up against the others in some key areas.

The comments to this entry are closed.

It happens to everyone. You reach to answer your phone, grab it wrong, and suddenly it’s falling — kerplunk! — onto the hard floor. For engineers, knowing how their products will stand up in scenarios like free falls is critical to achieving their safety and performance goals. To test their designs in these highly nonlinear, high-speed situations, they rely on a simulation methodology called explicit dynamics analysis.

Explicit dynamics is a time integration method used to perform dynamic simulations when speed is important. Explicit dynamics account for quickly changing conditions or discontinuous events, such as free falls, high-speed impacts, and applied loads. Because these “nonlinear dynamics” are integrated into the simulation, explicit dynamics is the preferred choice for simulating highly transient physical phenomena.

Explicit Dynamics Capabilities

Explicit dynamics tools help engineers to explore a wide range of challenges:

- Short-duration, complex or changing-body interactions (contact)

- Quasi-static loads (low strain rates)

- High-speed and hypervelocity impacts

- Severe loadings resulting in large material deformation

- Material failure

- Material fragmentation

- Penetration mechanics

- Space debris impact (hypervelocity)

- Sports equipment design

- Manufacturing processes with nonlinear plastic response

- Drop-test simulation

- Explosive loading

- Explosive forming

- Blast-structure interactions

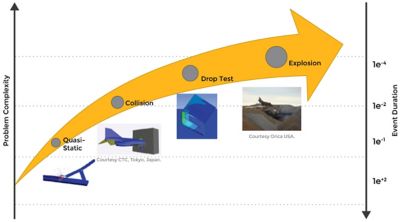

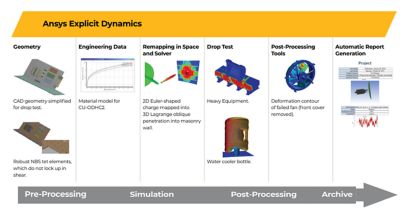

Figure 1. Ansys explicit dynamics tools help users meet solution requirements of various complexities based on problem details and user expertise.

If your product needs to survive impacts or short-duration, high-pressure loadings, you can improve its design with Ansys explicit dynamics solutions. Specialized problems require advanced analysis tools to accurately predict the effect of design considerations on product or process behavior. Gaining insight into such a complex reality is especially important when it is too expensive — or impossible — to perform physical testing.

The Ansys explicit dynamics suite enables you to capture the physics of short-duration events for products that undergo highly nonlinear, transient dynamic forces. Our specialized, accurate, and easy-to-use explicit dynamics tools have been designed to maximize user productivity.

With Ansys, engineers can gain insight into how a structure responds when subjected to severe loadings. Algorithms based on first principles accurately predict complex responses, such as large material deformations and failure, interactions between bodies, and fluids with rapidly deforming structures. Highly complex problems, especially ones with high strain rates and other phenomena that are difficult to converge with general-purpose implicit solution methods, can be resolved using sophisticated, state-of-the-art mathematical algorithms.

Defaults are safe and reasonable for most common problems, which means that you spend less time setting up and running problems and more time optimizing products for performance, durability, and cost, and removing design flaws.

In many cases, the accuracy of an explicit solution can be verified only through comparison with physical experiments. For some problems (such as explosions), it may be too expensive or even impossible to perform physical tests. Despite this, Ansys users around the world rely on the precision of our explicit simulation results.

While both implicit and explicit methods are used to solve time-dependent simulations, deciding which one to use depends on the problem being solved.

Use implicit dynamics when solving for dynamic finite element analysis (FEA) problems that involve mild nonlinearity and when large timesteps can be used. This includes:

- Static equilibriums.

- Slow, linear, and mildly nonlinear processes.

- Large time increments.

Use explicit dynamics when calculating highly complex and nonlinear problems involving rapid changes such as deformation or failure of material, such as:

- Drop tests.

- Impact and penetration.

- Breakage.

- Shock waves.

- Large deformations.

Ansys LS-DYNA

Ansys LS-DYNA is the most frequently used explicit simulation program in the world, capable of simulating applications like drop tests, impact and penetration, smashes and crashes, occupant safety, and more.

Ansys Explict Dynamics within Ansys Mechanical

Ansys Mechanical is the best-in-class finite element solver offering structural, thermal, acoustics, transient, and nonlinear capabilities to solve your most complex structural engineering problems.

Ansys Autodyn

Ansys Autodyn offers a range of models to represent complex physical phenomena such as the interaction of liquids, solids and gases; the phase transitions of materials; the propagation of shock waves; and even explosions.

For solving highly transient, highly nonlinear simulations, explicit dynamics is the preferred choice of time integration methods. To learn about the industry’s leading explicit simulation software, check out the Ansys LS-DYNA Multiphysics Solver.

В шеллах именно по WB DesignModeller — как я понимаю сделать солид, потом на него наложить mid-surface?

Или именно тип тела должен быть surface?

Тип — Surface. Не столько должен, сколько это разумно.

Справитесь ли Вы, просто используя функцию mid-surface, зависит от Вас и от геометрии. Скорее всего, придется поработать над геометрией чуть больше.

В целом, геометрия будет представлена оболочкой и объемными телами, а также, возможно, присоединенными массами.

Верна ли логика — максимально возможный размер элемента?

Шаг по времени, которым Вы недовольны, определяется самым маленьким элементом. Когда таких маленьких элементов несколько штук — может выручить Mass Scaling. В общем и целом лучше обходиться без них.

Логика — избегать ненужного локального измельчения сетки.

Начните с задачки попроще, замените свой грузовик на ящик из shell’ов. Обратите внимание как сетка влияет на шаг по времени(метод сетки Uniform Quad оптимальный). Потом усложняйте геометрию. Потом прицепите пару solid’ов в модель. Убедитесь, что контакты настроены правильно и ничего не разваливается.

Пока с такой задачкой справитесь, освоите практически все, что нужно для Вашего краш-теста.

ANSYS Explicit Dynamics Analysis Guide

ANSYS, Inc. Southpointe 2600 ANSYS Drive Canonsburg, PA 15317 [email protected] http://www.ansys.com (T) 724-746-3304 (F) 724-514-9494

Release 17.0 January 2016 ANSYS, Inc. is certified to ISO 9001:2008.

Copyright and Trademark Information © 2015 SAS IP, Inc. All rights reserved. Unauthorized use, distribution or duplication is prohibited. ANSYS, ANSYS Workbench, Ansoft, AUTODYN, EKM, Engineering Knowledge Manager, CFX, FLUENT, HFSS, AIM and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries. ICEM CFD is a trademark used by ANSYS, Inc. under license. CFX is a trademark of Sony Corporation in Japan. All other brand, product, service and feature names or trademarks are the property of their respective owners.

Disclaimer Notice THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION INCLUDE TRADE SECRETS AND ARE CONFIDENTIAL AND PROPRIETARY PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. The software products and documentation are furnished by ANSYS, Inc., its subsidiaries, or affiliates under a software license agreement that contains provisions concerning non-disclosure, copying, length and nature of use, compliance with exporting laws, warranties, disclaimers, limitations of liability, and remedies, and other provisions. The software products and documentation may be used, disclosed, transferred, or copied only in accordance with the terms and conditions of that software license agreement. ANSYS, Inc. is certified to ISO 9001:2008.

U.S. Government Rights For U.S. Government users, except as specifically granted by the ANSYS, Inc. software license agreement, the use, duplication, or disclosure by the United States Government is subject to restrictions stated in the ANSYS, Inc. software license agreement and FAR 12.212 (for non-DOD licenses).

Third-Party Software See the legal information in the product help files for the complete Legal Notice for ANSYS proprietary software and third-party software. If you are unable to access the Legal Notice, Contact ANSYS, Inc. Published in the U.S.A.

Table of Contents 1. Explicit Dynamics Analysis Guide Overview ………………………………………………………………………………. 1 2. Explicit Dynamics Workflow ……………………………………………………………………………………………………. 3 2.1. Introduction ……………………………………………………………………………………………………………………. 3 2.2. Create the Analysis System …………………………………………………………………………………………………. 4 2.3. Define Engineering Data ……………………………………………………………………………………………………. 4 2.4. Attach Geometry ……………………………………………………………………………………………………………… 4 2.5. Define Part Behavior …………………………………………………………………………………………………………. 6 2.6. Define Connections ………………………………………………………………………………………………………….. 7 2.6.1. Spot Welds in Explicit Dynamics Analyses ……………………………………………………………………… 8 2.6.2. Body Interactions in Explicit Dynamics Analyses …………………………………………………………….. 9 2.6.2.1. Properties for Body Interactions Folder ………………………………………………………………… 11 2.6.2.1.1. Contact Detection ……………………………………………………………………………………. 11 2.6.2.1.2. Formulation ……………………………………………………………………………………………. 13 2.6.2.1.3. Shell Thickness Factor and Nodal Shell Thickness …………………………………………… 14 2.6.2.1.4. Body Self Contact …………………………………………………………………………………….. 14 2.6.2.1.5. Element Self Contact ………………………………………………………………………………… 14 2.6.2.1.6. Tolerance ……………………………………………………………………………………………….. 15 2.6.2.1.7. Pinball Factor ………………………………………………………………………………………….. 15 2.6.2.1.8. Time Step Safety Factor …………………………………………………………………………….. 16 2.6.2.1.9. Limiting Time Step Velocity ……………………………………………………………………….. 16 2.6.2.1.10. Edge on Edge Contact …………………………………………………………………………….. 16 2.6.2.2. Interaction Type Properties for Body Interaction Object ………………………………………….. 16 2.6.2.2.1. Frictionless Type ……………………………………………………………………………………… 16 2.6.2.2.2. Frictional Type ………………………………………………………………………………………… 17 2.6.2.2.3. Bonded Type ………………………………………………………………………………………….. 18 2.6.2.2.4. Reinforcement Type …………………………………………………………………………………. 19 2.6.2.3. Identifying Body Interactions Regions for a Body …………………………………………………… 21 2.7. Setting Up Symmetry ………………………………………………………………………………………………………. 21 2.7.1. Explicit Dynamics Symmetry …………………………………………………………………………………….. 21 2.7.1.1. General Symmetry …………………………………………………………………………………………… 21 2.7.1.2. Global Symmetry Planes …………………………………………………………………………………… 22 2.7.2. Symmetry in an Euler Domain …………………………………………………………………………………… 22 2.8. Define Remote Points ……………………………………………………………………………………………………… 23 2.8.1. Explicit Dynamics Remote Points ……………………………………………………………………………….. 23 2.8.2. Explicit Dynamics Remote Boundary Conditions …………………………………………………………… 24 2.8.3. Initial Conditions on Remote Points ……………………………………………………………………………. 24 2.8.4. Constraints and Remote Points ………………………………………………………………………………….. 24 2.9. Apply Mesh Controls/Preview Mesh …………………………………………………………………………………… 27 2.10. Establish Analysis Settings ………………………………………………………………………………………………. 29 2.10.1. Analysis Settings for Explicit Dynamics Analyses …………………………………………………………. 33 2.10.1.1. Explicit Dynamics Step Controls ……………………………………………………………………….. 33 2.10.1.2. Explicit Dynamics Solver Controls ……………………………………………………………………… 37 2.10.1.3. Explicit Dynamics Euler Domain Controls …………………………………………………………… 41 2.10.1.4. Explicit Dynamics Damping Controls …………………………………………………………………. 42 2.10.1.5. Explicit Dynamics Erosion Controls ……………………………………………………………………. 43 2.10.1.6. Explicit Dynamics Output Controls ……………………………………………………………………. 44 2.10.1.7. Explicit Dynamics Data Management Settings …………………………………………………….. 47 2.10.1.8. Recommendations for Analysis Settings in Explicit Dynamics …………………………………. 47 2.10.1.9. Explicit Dynamics Analysis Settings Notes ………………………………………………………….. 51 2.11. Define Initial Conditions …………………………………………………………………………………………………. 52 Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

iii

Explicit Dynamics Analysis Guide 2.12. Apply Loads and Supports ……………………………………………………………………………………………… 52 2.12.1. Impedance Boundary …………………………………………………………………………………………….. 53 2.12.2. Detonation Point …………………………………………………………………………………………………… 56 2.13. Solve ………………………………………………………………………………………………………………………….. 60 2.13.1. Solving from Time = 0 …………………………………………………………………………………………….. 60 2.13.2. Resume Capability for Explicit Dynamics Analyses ……………………………………………………….. 60 2.13.2.1. Load and Constraint Behavior when Extending Analysis End Time ………………………….. 61 2.13.3. Explicit Dynamics Performance in Parallel ………………………………………………………………….. 62 2.14. Postprocessing …………………………………………………………………………………………………………….. 63 2.14.1. Solution Output ……………………………………………………………………………………………………. 63 2.14.2. Result Trackers ……………………………………………………………………………………………………… 63 2.14.2.1. Point Scoped Result Trackers for Explicit Dynamics ………………………………………………. 64 2.14.2.2. Body Scoped Result Trackers for Explicit Dynamics ………………………………………………. 69 2.14.2.3. Spring Result Trackers for Explicit Dynamics ……………………………………………………….. 73 2.14.2.4. Viewing and Filtering Result Tracker Graphs for Explicit Dynamics …………………………… 73 2.14.2.5. Force Reaction Result Trackers for Explicit Dynamics …………………………………………….. 74 2.14.3. Review Results ……………………………………………………………………………………………………… 75 2.14.4. Eroded Nodes in Explicit Dynamics Analyses ………………………………………………………………. 76 2.14.5. Euler Domain in Explicit Dynamics Analyses ……………………………………………………………….. 77 2.14.6. User Defined Results for Explicit Dynamics Analyses …………………………………………………….. 80 3. Transforming an Implicit Model to run in Explicit Dynamics ………………………………………………………. 87 3.1. When Implicit Models Can be Run in Explicit ………………………………………………………………………… 87 3.2. When to Consider an Explicit Analysis …………………………………………………………………………………. 88 3.2.1. Incorrect Model Setup ……………………………………………………………………………………………… 88 3.2.2. Large Deformations ………………………………………………………………………………………………… 89 3.2.3. Large Contact Models ……………………………………………………………………………………………… 90 3.2.4. Rigid Body Deformations ………………………………………………………………………………………….. 91 3.3. Setting up the Explicit Dynamics Analysis ……………………………………………………………………………. 92 3.3.1. Attaching an Explicit Dynamics System to an Existing Static Structural System ……………………. 92 3.3.2. Materials ……………………………………………………………………………………………………………….. 93 3.3.3. Meshing ………………………………………………………………………………………………………………… 93 3.3.3.1. Uniform Mesh Works Best …………………………………………………………………………………. 94 3.3.3.2. Midside Nodes not Used …………………………………………………………………………………… 94 3.3.3.3. Hex/Rectangular Mesh Elements most Effective ……………………………………………………. 95 3.3.4. Contact/Connections ………………………………………………………………………………………………. 95 3.3.4.1. Contacts Tab …………………………………………………………………………………………………… 95 3.3.4.2. Body Interactions Tab ………………………………………………………………………………………. 96 3.3.5. Boundary Conditions ………………………………………………………………………………………………. 96 3.3.5.1. Adjusting Load Cases for Reasonable Run Times ……………………………………………………. 96 3.3.5.2. Missing Boundary Conditions from Explicit Dynamics …………………………………………….. 97 3.3.5.3. Application of Boundary Conditions Using Steps …………………………………………………… 97 3.3.5.4. Avoiding Conflicting Boundary Conditions …………………………………………………………… 97 3.3.5.5. Initial Conditions …………………………………………………………………………………………….. 97 3.3.6. Analysis Settings …………………………………………………………………………………………………….. 98 3.3.6.1. End Time ……………………………………………………………………………………………………….. 98 3.3.6.2. Output Controls ……………………………………………………………………………………………… 98 3.4. Solver …………………………………………………………………………………………………………………………… 99 3.4.1. Timestep Controls …………………………………………………………………………………………………… 99 3.4.2. Analysis Setting Preference ……………………………………………………………………………………… 101 3.4.3. Solution Stability …………………………………………………………………………………………………… 101 3.4.3.1. Mass Scaling …………………………………………………………………………………………………. 101 3.4.3.2. Erosion ………………………………………………………………………………………………………… 102

iv

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Explicit Dynamics Analysis Guide 3.4.3.3. Damping …………………………………………………………………………………………………….. 103 3.4.3.4. Restarting an Analysis …………………………………………………………………………………….. 103 3.4.4. Solution Information ……………………………………………………………………………………………… 103 3.5. Postprocessing …………………………………………………………………………………………………………….. 104 3.5.1. Result Trackers ……………………………………………………………………………………………………… 105 3.5.2. Result Sets …………………………………………………………………………………………………………… 105 3.5.3. Improving your Simulation ……………………………………………………………………………………… 106 4. Applying Pre-Stress Effects for Explicit Analysis …………………………………………………………………….. 107 4.1. Recommended Guidelines for Pre-Stress Explicit Dynamics …………………………………………………… 107 4.2. Pre-Stress Object Properties ……………………………………………………………………………………………. 109 5. Using Explicit Dynamics to Define Initial Conditions for Implicit Analysis …………………………………. 111 5.1. Transfering Explicit Results to MAPDL ……………………………………………………………………………….. 111 6. Explicit Dynamics Theory Guide …………………………………………………………………………………………… 115 6.1. Why use Explicit Dynamics? …………………………………………………………………………………………….. 115 6.2. What is Explicit Dynamics? ……………………………………………………………………………………………… 115 6.2.1. The Solution Strategy …………………………………………………………………………………………….. 116 6.2.2. Basic Formulations ………………………………………………………………………………………………… 116 6.2.2.1. Implicit Transient Dynamics …………………………………………………………………………….. 117 6.2.2.2. Explicit Transient Dynamics ……………………………………………………………………………… 117 6.2.3. Time Integration ……………………………………………………………………………………………………. 118 6.2.3.1. Implicit Time Integration …………………………………………………………………………………. 118 6.2.3.2. Explicit Time Integration …………………………………………………………………………………. 118 6.2.3.3. Mass Scaling …………………………………………………………………………………………………. 120 6.2.4. Wave Propagation …………………………………………………………………………………………………. 120 6.2.4.1. Elastic Waves ………………………………………………………………………………………………… 121 6.2.4.2. Plastic Waves ………………………………………………………………………………………………… 121 6.2.4.3. Shock Waves …………………………………………………………………………………………………. 121 6.2.5. Reference Frame …………………………………………………………………………………………………… 122 6.2.5.1. Lagrangian and Eulerian Reference Frames ………………………………………………………… 122 6.2.5.2. Eulerian (Virtual) Reference Frame in Explicit Dynamics ………………………………………… 123 6.2.5.3. Key Concepts of Euler (Virtual) Solutions ……………………………………………………………. 125 6.2.5.3.1. Multiple Material Stress States ………………………………………………………………….. 126 6.2.5.3.2. Multiple Material Transport ……………………………………………………………………… 128 6.2.5.3.3. Supported Material Properties ………………………………………………………………….. 128 6.2.5.3.4. Known Limitations of Euler Solutions …………………………………………………………. 128 6.2.6. Explicit Fluid Structure Interaction (Euler-Lagrange Coupling) ……………………………………….. 128 6.2.6.1. Shell Coupling ………………………………………………………………………………………………. 130 6.2.6.2. Sub-cycling ………………………………………………………………………………………………….. 130 6.3. Analysis Settings …………………………………………………………………………………………………………… 131 6.3.1. Step Controls ……………………………………………………………………………………………………….. 131 6.3.2. Damping Controls …………………………………………………………………………………………………. 132 6.3.3. Solver Controls ……………………………………………………………………………………………………… 136 6.3.4. Erosion Controls ……………………………………………………………………………………………………. 144 6.4. Model Size Limitations in Explicit Dynamics ……………………………………………………………………….. 145 6.5. References …………………………………………………………………………………………………………………… 146 7. Material Models Used in Explicit Dynamics Analysis ……………………………………………………………….. 149 7.1. Introduction ………………………………………………………………………………………………………………… 149 7.2. Explicit Material Library ………………………………………………………………………………………………….. 151 7.3. Density ……………………………………………………………………………………………………………………….. 157 7.4. Linear Elastic ………………………………………………………………………………………………………………… 157 7.4.1. Isotropic Elasticity …………………………………………………………………………………………………. 157 7.4.2. Orthotropic Elasticity ……………………………………………………………………………………………… 158 Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

v

Explicit Dynamics Analysis Guide 7.4.3. Viscoelastic ………………………………………………………………………………………………………….. 158 7.5. Test Data ……………………………………………………………………………………………………………………… 159 7.6. Hyperelasticity ……………………………………………………………………………………………………………… 159 7.7. Plasticity ……………………………………………………………………………………………………………………… 164 7.7.1. Bilinear Isotropic Hardening ……………………………………………………………………………………. 165 7.7.2. Multilinear Isotropic Hardening ……………………………………………………………………………….. 165 7.7.3. Bilinear Kinematic Hardening ………………………………………………………………………………….. 166 7.7.4. Multilinear Kinematic Hardening ……………………………………………………………………………… 166 7.7.5. Johnson-Cook Strength ………………………………………………………………………………………….. 166 7.7.6. Cowper-Symonds Strength ……………………………………………………………………………………… 168 7.7.7. Steinberg-Guinan Strength ……………………………………………………………………………………… 169 7.7.8. Zerilli-Armstrong Strength ………………………………………………………………………………………. 170 7.8. Brittle/Granular …………………………………………………………………………………………………………….. 172 7.8.1. Drucker-Prager Strength Linear ……………………………………………………………………………….. 172 7.8.2. Drucker-Prager Strength Stassi ………………………………………………………………………………… 173 7.8.3. Drucker-Prager Strength Piecewise …………………………………………………………………………… 174 7.8.4. Johnson-Holmquist Strength Continuous ………………………………………………………………….. 175 7.8.5. Johnson-Holmquist Strength Segmented ………………………………………………………………….. 177 7.8.6. RHT Concrete Strength …………………………………………………………………………………………… 179 7.8.7. MO Granular ………………………………………………………………………………………………………… 184 7.9. Equations of State …………………………………………………………………………………………………………. 185 7.9.1. Background …………………………………………………………………………………………………………. 185 7.9.2. Bulk Modulus ……………………………………………………………………………………………………….. 186 7.9.3. Shear Modulus ……………………………………………………………………………………………………… 186 7.9.4. Ideal Gas EOS ……………………………………………………………………………………………………….. 186 7.9.5. Polynomial EOS …………………………………………………………………………………………………….. 187 7.9.6. Shock EOS Linear …………………………………………………………………………………………………… 189 7.9.7. Shock EOS Bilinear …………………………………………………………………………………………………. 190 7.9.8. JWL EOS ………………………………………………………………………………………………………………. 192 7.10. Porosity …………………………………………………………………………………………………………………….. 194 7.10.1. Porosity-Crushable Foam ………………………………………………………………………………………. 194 7.10.2. Compaction EOS Linear ………………………………………………………………………………………… 197 7.10.3. Compaction EOS Non-Linear …………………………………………………………………………………. 198 7.10.4. P-alpha EOS ……………………………………………………………………………………………………….. 200 7.11. Failure ……………………………………………………………………………………………………………………….. 203 7.11.1. Plastic Strain Failure ……………………………………………………………………………………………… 205 7.11.2. Principal Stress Failure ………………………………………………………………………………………….. 205 7.11.3. Principal Strain Failure ………………………………………………………………………………………….. 206 7.11.4. Stochastic Failure ………………………………………………………………………………………………… 207 7.11.5. Tensile Pressure Failure …………………………………………………………………………………………. 208 7.11.6. Crack Softening Failure …………………………………………………………………………………………. 209 7.11.7. Johnson-Cook Failure …………………………………………………………………………………………… 211 7.11.8. Grady Spall Failure ……………………………………………………………………………………………….. 212 7.12. Strength ……………………………………………………………………………………………………………………. 213 7.13. Thermal Specific Heat …………………………………………………………………………………………………… 214 7.14. Rigid Materials ……………………………………………………………………………………………………………. 214 7.15. References …………………………………………………………………………………………………………………. 214 8. Using ANSYS LS-DYNA for an Explicit Dynamics Analysis ………………………………………………………… 217 8.1. How to use the Explicit Dynamics LS-DYNA System ……………………………………………………………… 217 8.2. Supported LS-DYNA Keywords ………………………………………………………………………………………… 217 8.3. LS-DYNA General Descriptions ………………………………………………………………………………………… 246 Index …………………………………………………………………………………………………………………………………….. 249

vi

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Chapter 1: Explicit Dynamics Analysis Guide Overview ANSYS Explicit Dynamics is a transient explicit dynamics Workbench application that can perform a variety of engineering simulations, including the modeling of nonlinear dynamic behaviour of solids, fluids, gases and their interaction. Additionally, the Explicit Dynamics (LS-DYNA Export) system is available to export the model in LS-DYNA .k file format for subsequent analysis with the LS-DYNA solver. A typical simulation consists of setting up the model, interactions and the applied loads, solving the model’s nonlinear dynamic response over time for the loads and interactions, then examining the details of the response with a variety of available tools. The Explicit Dynamics application has objects arranged in a tree structure that guide you through the different steps of a simulation. By expanding the objects, you expose the details associated with the object, and you can use the corresponding tools and specification tables to perform that part of the simulation. Objects are used, for example, to define environmental conditions such as contact surfaces and loadings, and to define the types of results you want to have available for review. The following sections describe in detail how to use the Explicit Dynamics application to set up and run a simulation: • Explicit Dynamics Workflow (p. 3) • Transforming an Implicit Model to run in Explicit Dynamics (p. 87) • Applying Pre-Stress Effects for Explicit Analysis (p. 107) • Using Explicit Dynamics to Define Initial Conditions for Implicit Analysis (p. 111) • Explicit Dynamics Theory Guide (p. 115) • Material Models Used in Explicit Dynamics Analysis (p. 149) The following section discusses how to solve an Explicit Dynamics (LS-DYNA Export) system to produce the LS-DYNA keyword file: • Using ANSYS LS-DYNA for an Explicit Dynamics Analysis (p. 217)

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

1

2

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Chapter 2: Explicit Dynamics Workflow To learn how to perform an analysis, see Create Analysis System in the ANSYS Mechanical User’s Guide. Note that the features available may differ from one solver to another. To perform analyses that are beyond those available using Workbench, you can insert a Commands object in the tree. This chapter contains the following topics: 2.1. Introduction 2.2. Create the Analysis System 2.3. Define Engineering Data 2.4. Attach Geometry 2.5. Define Part Behavior 2.6. Define Connections 2.7. Setting Up Symmetry 2.8. Define Remote Points 2.9. Apply Mesh Controls/Preview Mesh 2.10. Establish Analysis Settings 2.11. Define Initial Conditions 2.12. Apply Loads and Supports 2.13. Solve 2.14. Postprocessing

2.1. Introduction You can perform a transient explicit dynamics analysis in the Mechanical application using an Explicit Dynamics system. Additionally, the Explicit Dynamics (LS-DYNA Export) system is available to export the model in LS-DYNA .k file format for subsequent analysis with the LS-DYNA solver. Unless specifically mentioned otherwise, this section addresses both the Explicit Dynamics and Explicit Dynamics (LS-DYNA Export) systems. Special conditions for the Explicit Dynamics (LS-DYNA Export) system are noted where pertinent. An explicit dynamics analysis is used to determine the dynamic response of a structure due to stress wave propagation, impact or rapidly changing time-dependent loads. Momentum exchange between moving bodies and inertial effects are usually important aspects of the type of analysis being conducted. This type of analysis can also be used to model mechanical phenomena that are highly nonlinear. Nonlinearities may stem from the materials, (for example, hyperelasticity, plastic flows, failure), from contact (for example, high speed collisions and impact) and from the geometric deformation (for example, buckling and collapse). Events with time scales of less than 1 second (usually of order 1 millisecond) are efficiently simulated with this type of analysis. For longer time duration events, consider using a Transient analysis system. The time step used in an explicit dynamics analysis is constrained to maintain stability and consistency via the CFL condition, that is, the time increment is proportional to the smallest element dimension in the model and inversely proportional to the sound speed in the materials used. Time increments are

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

3

Explicit Dynamics Workflow usually on the order of 1 microsecond and therefore thousands of time steps (computational cycles) are usually required to obtain the solution. An explicit dynamics analysis typically includes many different types of nonlinearities including large deformations, large strains, plasticity, hyperelasticity, material failure etc. This section contains the following topics: An explicit dynamics analysis can contain both rigid and flexible bodies. For rigid/flexible body dynamic simulations involving mechanisms and joints you may wish to consider using either the Transient Structural Analysis or Rigid Dynamics Analysis options.

Note The intent of this document is to provide an overview of an explicit dynamics analysis. Consult our technical support department to obtain a more thorough treatment of this topic.

2.2. Create the Analysis System For general information about creating an analysis system see Create Analysis System in the ANSYS Mechanical User’s Guide. From the Toolbox drag an Explicit Dynamics or an Explicit Dynamics (LS-DYNA Export) template to the Project Schematic.

Note Explicit dynamics analyses only support the mm, mg, ms solver unit system. The Explicit Dynamics solver is double precision.

2.3. Define Engineering Data For general information about defining engineerng data, see Define Engineering Data in the ANSYS Mechanical User’s Guide Material properties can be linear elastic or orthotropic. Many different forms of material nonlinearity can be represented including hyperelasticity, rate and temperature dependant plasticity, pressure dependant plasticity, porosity, material strength degradation (damage), material fracture/failure/fragmentation. For a detailed discussion on material models used in Explicit Dynamics, refer to Material Models Used in Explicit Dynamics Analysis (p. 149). Density must always be specified for materials used in an explicit dynamics analysis. Data for a range of materials is available in the Explicit material library.

2.4. Attach Geometry For general information about attaching a geometry to a system, see Attach Geometry in the ANSYS Mechanical User’s Guide. Solid, Surface, and Line bodies can be present in an Explicit Dynamics analysis.

4

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Attach Geometry Only symmetric cross sections are supported for line bodies in Explicit Dynamics analyses, except for the Explicit Dynamics (LS-DYNA Export) systems. The following cross sections are not supported: TSections, L-Sections, Z-Sections, Hat sections, Channel Sections. For I-Sections, the two flanges must have the same thickness. For rectangular tubes, opposite sides of the rectangle must be of the same thickness. For LS-DYNA Export systems all available cross sections in DesignModeler will be exported for analysis with the LS-DYNA solver. However there are some limitations in the number of dimensions that the LS-DYNA solver supports for the Z, Hat and Channel cross sections. For more information consult the LS-DYNA Keywords manual. To prevent the generation of unnecessarily small elements (and long run times) try using DesignModeler to remove unwanted “small” features or holes from your geometry. Thickness can be specified for selected faces on a surface body by inserting a thickness object. Constant, tabular, and functional thickness are all supported. Symmetry is not supported when exporting to the LS-DYNA .k file. Stiffness Behavior Flexible behavior can be assigned to any body type. Rigid behavior can be applied to Solid, Surface, and Line bodies. Coordinate System Local Cartesian coordinate systems can be assigned to bodies. These will be used to define the material directions when using the Orthotropic Elasticity property in a material definition. The material directions 1, 2, 3 will be aligned with the local x, y and z axes of the local coordinate system.

Note Cylindrical coordinate systems assigned to bodies are not supported for Explicit Dynamics systems. Cylindrical coordinate systems are only supported to define rotational displacement or velocity constraints. Reference Temperature This option defines the initial (time=0.0) temperature of the body. Reference Frame Available for solid bodies when an Explicit Dynamics system is part of the solution; the user has the option of setting the Reference Frame to Lagrangian (default) or Eulerian (Virtual). If Stiffness Behavior is defined as Rigid, Eulerian is not a valid setting. Rigid Materials For bodies defined to have rigid stiffness, only the Density property of the material associated with the body will be used. For Explicit Dynamics systems all rigid bodies must be discretized with a Full Mesh or the Rigid Body Behavior must be defined as Dimensionally Reduced. The Full Mesh option will be specified by default for the Explicit meshing physics preference. The mass and inertia of the rigid body will be derived from the elements and material density for each body. Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

5

Explicit Dynamics Workflow By default, a kinematic rigid body is defined and its motion will depend on the resultant forces and moments applied to it through interaction with other Parts of the model. Elements filled with rigid materials can interact with other regions via contact. Constraints can only be applied to an entire rigid body. For example, a fixed displacement cannot be applied to one edge of a rigid body, it must be applied to the whole body.

Note • 2-D Explicit Dynamics analyses are supported for Plane Strain and Axisymmetric behaviors. • Only symmetric cross-sections are supported for line bodies • Flexible and rigid bodies cannot be combined in Multi-body Parts. Bonded connections can be applied to connect rigid and flexible bodies • The Thickness Mode and Offset Type fields for surface bodies are not supported for Explicit Dynamics systems • Initial over-penetrations of nodes/elements of different bodies should be avoided or minimized if sliding contact is to be used. There are several methods available in Workbench to remove initial penetration

2.5. Define Part Behavior For general information about defining parts, see Define Part Behavior in the ANSYS Mechanical User’s Guide. Nonlinear effects are always accounted for in explicit dynamics analysis. Parts may be defined as rigid or flexible. In the solver, rigid parts are represented by a single point that carries the inertial properties together with a discretized exterior surface that represents the geometry. Rigid bodies should be meshed using similar Method mesh controls as those used for flexible bodies. The inertial properties used in the solver will be derived from the discretized representation of the body and the material density and hence may differ slightly from the values presented in the properties of the body in the Mechanical application GUI. At least one flexible body must be specified when using the ANSYS Autodyn solver. The solver requires this in order to calculate the time-step increments. In the absence of a flexible body, the time-step becomes underdefined. The boundary conditions allowed for the rigid bodies with explicit dynamics are: • Connections – Contact Regions: Frictionless, Frictional and Bonded. – Body Interactions: Frictionless, Frictional and Bonded. Bonded body interactions are not supported for LS-DYNA Export. – For ANSYS Autodyn, rigid bodies may not be bonded to other rigid bodies. • Initial Conditions: Velocity, Angular Velocity • Supports: Displacement, Fixed Support and Velocity.

6

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Define Connections • Loads: Pressure and Force. Force is not supported for ANSYS Autodyn. For an Explicit Dynamics analysis, the following postprocessing features are available for rigid bodies: • Results and Probes: Deformation only — that is, Displacement, Velocity. • Result Trackers: Body average data only. If a multibody part consists only of rigid bodies, all of which share the same material assignment, the part will act as a single rigid body, even if the individual bodies are not physically connected.

2.6. Define Connections For general information about defining connections, see Define Connections in the ANSYS Mechanical User’s Guide Line body to line body contact is possible if: • Contact Detection should be set to Proximity Based in the Body Interactions Details view. • Edge on Edge is set to Yes in the Body Interactions Details view. • The Interaction Type is defined as Frictional or Frictionless – bonded interactions and connections are not supported for line bodies. • LS-DYNA Export systems export the *CONTACT_AUTOMATIC_GENERAL and *CONTACT_AUTOMATIC_SINGLE_SURFACE keywords when a friction or frictionless Body Interaction is scoped to geometry that contains line bodies. The keywords handle contacts between line bodies only, and line bodies to other body types respectively. In the case where the Body Interaction is scoped to only line bodies, then only the *CONTACT_AUTOMATIC_GENERAL keyword is exported. Reinforcement body interaction should be supported in the case when only line bodies are scoped to a Body Interaction of Type = Reinforcement. The line bodies will then be tied to any solid body that they intersect. Reinforcement body interactions are not supported for LS-DYNA Export systems or for 2D Explicit Dynamics analyses. However utilizing Keyword Snippets under Contact Region objects should provide a suitable alternative. Body Interactions (p. 9), Contact and Spot Welds are all valid in explicit dynamics analyses. Frictional, Frictionless and Bonded body interactions and contact options are available. Conditionally bonded contact can be simulated using the breakable property of each bonded region. Spot Welds can also be made to fail using the breakable property. Joints and Beam connections are not supported for explicit dynamics analyses. Springs are not supported for Explicit Dynamics (LS-DYNA Export) analyses. The Contact Tool is also not applicable to explicit dynamics analyses. For Explicit Dynamics (LS-DYNA Export) systems, bonded body interactions are not supported. Also, Contact Region objects with Auto Asymmetric Behavior or just Asymmetric Behavior are treated the same. Symmetric Behavior will create a _SURFACE_TO_SURFACE keyword for the contact and an Asymmetric Behavior will create a _NODES_TO_SURFACE keyword. For Explicit Dynamics (LS-DYNA Export) systems, contacts between line bodies and solids can be implemented using the Keyword Snippets facility available under the Manual Contact Region objects.

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

7

Explicit Dynamics Workflow Bonded contact is not supported in an explicit dynamics analysis for bodies that have their Reference Frame set to Eulerian (Virtual). A solver warning is shown to let the user know that such bodies will be ignored for bonds. Bonded contact is not support in a 2D explicit dynamics analysis. To avoid hourglassing problems, remote points should be used instead of bonded contact in certain situations. Bonds are not recommended for joining tetrahedral meshes. Use multibodied parts or remote points instead. By default, a Body Interaction object will be automatically inserted in the Mechanical application tree and will be scoped to all bodies in the model. This object activates frictionless contact behavior between all bodies that come into proximity during the analysis.

2.6.1. Spot Welds in Explicit Dynamics Analyses Spot welds provide a mechanism to rigidly connect two discrete points in a model and can be used to represent welds, rivets, bolts, etc. The points usually belong to two different surfaces and are defined on the geometry (see DesignModeler help). During the solver initialization process, the two points defining each spot weld will be connected by a rigid beam element. Additionally, rigid beam elements will be generated on each surface to enable transfer of rotations at the spot weld location (see figure below). If the point of the spot weld lies on a shell body, both translational and rotational degrees of freedom will be linked at the connecting point. If the point of the spot weld lies on a surface of a solid body, additional rigid beam elements will be generated to enable transfer of rotations at the spot weld location. Spot welds can be released during a simulation using the Breakable Stress or Force option. If the stress criteria is selected the user will be asked to define an effective cross sectional area. This is used to convert the defined stress limits into equivalent force limits. A spot weld will break (release) if the following criteria is exceeded (2.1)

Where: fn and fs are normal and shear interface forces Sn and Ss are the maximum allowed normal and shear force limits n and s are user defined exponential coefficients Note that the normal interface force fn is non-zero for tensile values only. After failure of the spot weld the rigid body connecting the points is removed from the simulation. Spot welds of zero length are permitted. However, if such spot welds are defined as breakable the above failure criteria is modified since local normal and shear directions cannot be defined. A modified criteria is used with global forces (2.2)

8

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Define Connections Where,

are the force differences across the spot weld in the global coordinate system.

Note A spot weld is equivalent to a rigid body and as such multiple nodal boundary conditions cannot be applied to spot welds.

2.6.2. Body Interactions in Explicit Dynamics Analyses Within an explicit dynamics analysis, the body interaction feature represents contact between bodies and includes settings that allow you to control these interactions. If the geometry you use has two or more bodies in contact, a Body Interactions object folder appears by default under Connections in the tree. Included in a Body Interactions folder are one or more Body Interaction objects, with each object representing a contact pair. You can also manually add these two objects: • To add a Body Interactions folder, highlight the Connections folder and choose Body Interactions from the toolbar. A Body Interactions folder is added and includes one Body Interaction object. • To add a Body Interaction object to an existing Body Interactions folder, highlight the Connections folder, the Body Interactions folder, or an existing Body Interaction object, and choose Body Interaction from the toolbar.

General Notes Each Body Interaction object activates an interaction for the bodies scoped in the object. With body interactions, contact detection is completely automated in the solver. At any time point during the Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

9

Explicit Dynamics Workflow analysis any node of the bodies scoped in the interaction may interact with any face of the bodies scoped in the interaction. The interactions are automatically detected during the solution. The default frictionless interaction type that is scoped to all bodies activates frictionless contact between any external node and face that may come into contact in the model during the analysis. To improve the efficiency of analyses involving large number of bodies, you are advised to suppress the default frictionless interaction that is scoped to all bodies, and instead insert additional Body Interaction objects which limit interactions to specific bodies. The union of all frictional/frictionless body interactions defines the matrix of possible body interactions during the analysis. For example, in the model shown below: • Body A is traveling towards body B and we require frictional contact to occur. A frictional body interaction type scoped only to bodies A and B will achieve this. Body A will not come close to body C during the analysis so it does not need to be included in the interaction. • Body B is bonded to body C. A bonded body Interaction type, scoped to bodies B and C will achieve this. • If the bond between bodies B and C breaks during the analysis, we want frictional contact to take place between bodies B and C. A frictional body interaction type scoped only to bodies B and C will achieve this.

A bonded body interaction type can be applied in addition to a frictional/frictionless body interaction. A reinforcement body interaction type be can be applied in addition to a frictional/frictionless body interaction. Object property settings are included in the Details view for both the Body Interactions folder and the individual Body Interaction objects. Refer to the following sections for descriptions of these properties. 2.6.2.1. Properties for Body Interactions Folder 2.6.2.2. Interaction Type Properties for Body Interaction Object 2.6.2.3. Identifying Body Interactions Regions for a Body

10

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Define Connections

2.6.2.1. Properties for Body Interactions Folder All properties for the Body Interactions folder are included in an Advanced category and define the global properties of the contact algorithm for the analysis. These properties are applied to all Body Interaction objects and to all frictional and frictionless manual contact regions. This section includes descriptions of the following properties for the Body Interactions folder: 2.6.2.1.1. Contact Detection 2.6.2.1.2. Formulation 2.6.2.1.3. Shell Thickness Factor and Nodal Shell Thickness 2.6.2.1.4. Body Self Contact 2.6.2.1.5. Element Self Contact 2.6.2.1.6.Tolerance 2.6.2.1.7. Pinball Factor 2.6.2.1.8.Time Step Safety Factor 2.6.2.1.9. Limiting Time Step Velocity 2.6.2.1.10. Edge on Edge Contact

2.6.2.1.1. Contact Detection The available choices are described below.

Trajectory The trajectory of nodes and faces included in frictional or frictionless contact are tracked during the computation cycle. If the trajectory of a node and a face intersects during the cycle a contact event is detected. The trajectory contact algorithm is the default and recommended option in most cases for contact in Explicit Dynamics analyses. Contacting nodes/faces can be initially separated or coincident at the start of the analysis. Trajectory based contact detection does not impose any constraint on the analysis time step and therefore often provides the most efficient solution. Note that nodes which penetrate into another element at the start of the simulation will be ignored for the purposes of contact and thus should be avoided. To generate duplicate conforming nodes across a contact interface: 1. Use the multibody part option in DesignModeler and set Shared Topology to Imprint. 2. For meshing, use Contact Sizing, the Arbitrary match control or the Match mesh Where Possible option of the Patch Independent mesh method.

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

11

Explicit Dynamics Workflow

Proximity Based The external faces, edges and nodes of a mesh are encapsulated by a contact detection zone. If during the analysis a node enters this detection zone, it will be repelled using a penalty based force.

Note • An additional constraint is applied to the analysis time step when this contact detection algorithm is selected. The time step is constrained such that a node cannot travel through a fraction of the contact detection zone size in one cycle. The fraction is defined by the Time Step Safety Factor (p. 16) described below. For analyses involving high velocities, the time step used in the analysis is often controlled by the contact algorithm. • The initial geometry/mesh must be defined such that there is a physical gap/separation of at least the contact detection zone size between nodes and faces in the model. The solver will give error messages if this criteria is not satisfied. This constraint means this option may not be practical for very complex assemblies. • Proximity Based Contact is not supported in 2D explicit dynamics analyses.

12

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Define Connections

2.6.2.1.2. Formulation This property is available if Contact Detection is set to Trajectory. The available choices are described below.

Penalty If contact is detected, a local penalty force is calculated to push the node involved in the contact event back to the face. Equal and opposite forces are calculated on the nodes of the face in order to conserve linear and angular momentum. Trajectory based penalty force,

Proximity based penalty force, Where: D is the depth of penetration M is the effective mass of the node (N) and face (F) Δt is the simulation time step

Note • Kinetic energy is not necessarily conserved. You can track conservation of energy in contact using the Solution Information object, the Solution Output, or one of the energy summary result trackers. • The applied penalty force will push the nodes back towards the true contact position during the cycle. However, it will usually take several cycles to satisfy the contact condition.

Decomposition Response All contacts that take place at the same point in time are first detected. The response of the system to these contact events is then calculated to conserve momentum and energy. During this process, forces are calculated to ensure that the resulting position of nodes and faces does not result in further penetration at that time point.

Note • The decomposition response algorithm cannot be used in combination with bonded contact regions. The formulation will be automatically switch to penalty if bonded regions are present in the model. • The decomposition response algorithm is more impulsive (in a given cycle) than the penalty method. This can give rise to large hourglass energies and energy errors.

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

13

Explicit Dynamics Workflow

2.6.2.1.3. Shell Thickness Factor and Nodal Shell Thickness These properties are available if the geometry includes one or more surface bodies and if Contact Detection is set to Trajectory. The Shell Thickness Factor allows you to control the effective thickness of surface bodies used in the contact. You can specify a value between 0.0 and 1.0. • A value of 0.0 means that contact will ignore the physical thickness of the surface body and the contact surface will be coincident with the mid-plane of the shell • A value of 1.0 means that the contact shell thickness will be equal to the physical shell thickness. The contact surface will be offset from the mid-plane of the shell by half the shell thickness (on both sides of the shell) Nodal Shell Thickness is only active when the Shell Thickness Factor value is not zero (0). It allows you to obtain the most accurate shell to shell contact by improving on the Shell Thickness Factor approach. • When set to Yes, contact between shells is improved by eliminating the inherent small overlap that may occur even when the Shell Thickness Factor is set to 1.0. Essentially this setting (along with a thickness factor of 1.0) will provide the most accurate shell thickness contact behaviour. • When set to No, the contact shell thickness will be determined by the value of the Shell Thickness Factor and the nodal shell thickness will not have any effect. When set to Program Controlled, the behavior of nodal shell thickness is determined by the Analysis Settings Preference Type (p. 47).

2.6.2.1.4. Body Self Contact When set to Yes, the contact detection algorithm will check for external nodes of a body contacting with faces of the same body in addition to other bodies. This is the most robust option since all possible external contacts should be detected. When set to No, the contact detection algorithm will only check for external nodes of a body contacting with external faces of other bodies. This setting reduces the number of possible contact events and can therefore improve efficiency of the analysis. This option should not be used if a body is likely to fold onto itself during the analysis, as it would during plastic buckling for example. When set to Program Controlled, the behavior of self contact is determined by the Analysis Settings Preference Type (p. 47). Presented below is an example of a model that includes self impact.

2.6.2.1.5. Element Self Contact When set to Yes, automatic erosion (removal of elements) is enabled when an element deforms such that one of its nodes comes within a specified distance of one of its faces. In this situation, elements

14

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Define Connections are removed before they become degenerated. Element self contact is very useful for impact penetration examples where removal of elements is essential to allow generation of a hole in a structure.

When set to Program Controlled, the behavior of self contact is determined by the Analysis Settings Preference Type (p. 47).

2.6.2.1.6. Tolerance This property is available if Contact Detection is set to Trajectory and Element Self Contact is set to Yes. Tolerance defines the size of the detection zone for element self contact when the trajectory contact option is used. (see Element Self Contact (p. 14)). The value input is a factor in the range 0.1 to 0.5. This factor is multiplied by the smallest characteristic dimension of the elements in the mesh to give a physical dimension. A setting of 0.5 effectively equates to 50% of the smallest element dimension in the model.

Note The smaller the fraction the more accurate the solution.

2.6.2.1.7. Pinball Factor This property is available if Contact Detection is set to Proximity Based. The pinball factor defines the size of the detection zone for proximity based contact. The value input is a factor in the range 0.1 to 0.5. This factor is multiplied by the smallest characteristic dimension of the elements in the mesh to give a physical dimension. A setting of 0.5 effectively equates to 50% of the smallest element dimension in the model.

Note The smaller the fraction the more accurate the solution. The time step in the analysis could be reduced significantly if small values are used (see Time Step Safety Factor (p. 16)).

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

15

Explicit Dynamics Workflow

2.6.2.1.8. Time Step Safety Factor This property is available if Contact Detection is set to Proximity Based. For proximity based contact, the time step used in the analysis is additionally constrained by contact such that in one cycle, a node in the model cannot travel more than the detection zone size, multiplied by a safety factor. The safety factor is defined with this property and the recommended default is 0.2. Increasing the factor may increase the time step and hence reduce runtimes, but may also lead to missed contacts. The maximum value you can specify is 0.5.

2.6.2.1.9. Limiting Time Step Velocity This property is available if Contact Detection is set to Proximity Based. For proximity based contact, this setting limits the maximum velocity that will be used to compute the proximity based contact time step calculation.

2.6.2.1.10. Edge on Edge Contact This property is available if Contact Detection is set to Proximity Based. By default, contact events in Explicit Dynamics are detected by nodes impacting faces. Use this option to extend the contact detection to include discrete edges impacting other edges in the model.

Note This option is numerically intensive and can significantly increase runtimes. It is recommended that you compare results with and without edge contact to make sure this feature is required. A model with edge on edge contact cannot be run in parallel.

2.6.2.2. Interaction Type Properties for Body Interaction Object This section includes descriptions of the interaction types for the Body Interaction object: 2.6.2.2.1. Frictionless Type 2.6.2.2.2. Frictional Type 2.6.2.2.3. Bonded Type 2.6.2.2.4. Reinforcement Type

2.6.2.2.1. Frictionless Type Setting Type to Frictionless activates frictionless sliding contact between any exterior node and any exterior face of the scoped bodies. Individual contact events are detected and tracked during the analysis. The contact is symmetric between bodies (that is, each node will belong to a master face impacted by adjacent slave nodes; each node will also act as a slave impacting a master face).

Supported Connections Explicit Dynamics Connection Geometry Volume

16

Volume

Shell

Line

Yes

Yes

Yes

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Define Connections Connection Geometry

Volume

Shell

Line

Shell

Yes

Yes

Yes

Line

Yes

Yes

*Yes

*Only for Contact Detection = Proximity Based and Edge on Edge Contact = Yes (This option switches on contact between ALL lines / bodies / edges, that is, there is no dependence on the scoping selection of body interactions.) Explicit Dynamics (LS-DYNA Export) Connection Geometry

Volume

Shell

Line

Volume

Yes

Yes

No

Shell

Yes

Yes

No

Line

No

No

No

2.6.2.2.2. Frictional Type Descriptions of the following properties are also addressed in this section: • Friction Coefficient • Dynamic Coefficient • Decay Constant Setting Type to Frictional activates frictional sliding contact between any exterior node and any exterior face of the scoped bodies. Individual contact events are detected and tracked during the simulation. The contact is symmetric between bodies (that is, each node will belong to a master face impacted by adjacent slave nodes, each node will also act as a slave impacting a master face). Friction Coefficient: A non-zero value will activate Coulomb type friction between bodies (F = μR). The relative velocity (ν) of sliding interfaces can influence frictional forces. A dynamic frictional formulation for the coefficient of friction can be used. (2.3) where = friction coefficient = dynamic coefficient of friction β = exponential decay coefficient ν = relative sliding velocity at point of contact Non-zero values of the Dynamic Coefficient and Decay Constant should be used to apply dynamic friction.

Supported Connections Explicit Dynamics Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

17

Explicit Dynamics Workflow Connection Geometry

Volume

Shell

Line

Volume

Yes

Yes

Yes

Shell

Yes

Yes

Yes

Line

Yes

Yes

*Yes

*Only for Contact Detection = Proximity Based and Edge on Edge Contact = Yes (This option switches on contact between ALL lines / bodies / edges, that is, there is no dependence on the scoping selection of body interactions.) Explicit Dynamics (LS-DYNA Export) Connection Geometry

Volume

Shell

Line

Volume

Yes

Yes

No

Shell

Yes

Yes

No

Line

No

No

No

2.6.2.2.3. Bonded Type Descriptions of the following properties are also addressed in this section: • Maximum Offset • Breakable – Stress Criteria → Normal Stress Limit → Normal Stress Exponent → Shear Stress Limit → Shear Stress Exponent External nodes of bodies included in bonded interactions will be tied to faces of bodies included in the interaction if the distance between the external node and the face is less than the value (tolerance) defined by the user in Maximum Offset. The solver automatically detects the bonded nodes/faces during the initialization phase of the analysis. Note that it is important to select an appropriate value for the Maximum Offset (tolerance). The automatic search will bond everything together which is found within this value (tolerance). Use the custom variable BOND_STATUS to check bonded connections in Explicit Dynamics. The variable records the number of nodes bonded to the faces on an element during the analysis. This can be used not only to verify that initial bonds are generated appropriately, but also to identify bonds that break during the simulation. Maximum Offset defines the tolerance used at initialization to determine whether a node is bonded to a face. Breakable = No implies that the bond will remain throughout the analysis.

18

Release 17.0 — © SAS IP, Inc. All rights reserved. — Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Define Connections Breakable = Stress Criteria implies that the bond may break (or be released) during the analysis. The criteria for breaking a bond is defined as: (2.4) where = Normal Stress Limit n = Normal Stress Exponent = Shear Stress Limit m = Shear Stress Exponent The options in the Advanced section are all currently ignored by the Explicit solver, including the Advanced > Pinball region option. The tolerance must be defined via the Maximum Offset value and is only used at initialization.

Supported Connections Explicit Dynamics Connection Geometry

Volume

Shell

Line

Volume

Yes

Yes

Yes

Shell

Yes

Yes

Yes

Line

Yes